+86 022 2376 3704

+86 022 2376 3704

Dec. 04, 2025

In marine engineering, underground utility tunnels, and long-span bridges, HDPE coated prestressed steel strands are the preferred choice due to their superior corrosion resistance and ease of construction. However, due to material properties and the construction environment, issues such as coating damage, failure under extreme temperature and humidity conditions, and high-stress cracking may still occur. As a source supplier deeply rooted in the prestressed materials field, we can help you identify the core problems and provide targeted, practical solutions to safeguard the quality of projects.

I. Coating Susceptible to Physical Damage

Although HDPE coatings possess a certain degree of toughness, they are prone to scratches and damage if frequently subjected to impacts and scrapes during construction. Once the coating cracks, corrosive media such as moisture and chloride ions will directly contact the steel strand substrate. Direct contact with these corrosive media leads to extremely high costs for subsequent rust removal and repair. Burrs on the edges of the holes during threading, accidental impacts from construction machinery, and compression during material stacking are also contributing factors to coating damage.

Solutions:

1. Conduct a comprehensive inspection of the prestressed ducts before construction. Sand down both ends and the interior of the ducts to remove burrs. If necessary, install smooth guide sleeves at the duct inlets to reduce coating friction and scratching during strand threading.

2. Use matching wear-resistant strand threading guides. Control the traction speed during threading (recommended ≤5m/min) to avoid severe collisions between the steel strands and the inner wall of the guide.

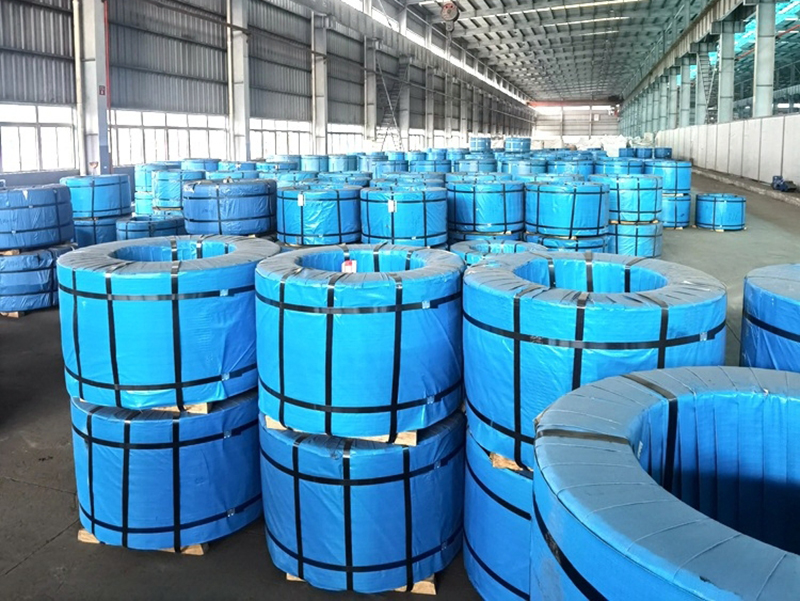

3. Materials should be stacked on a rubber mat or wooden pallet at least 3.0cm thick on the ground. Direct contact with sharp objects is prohibited, and the stacking height should not exceed 1.5m to prevent damage to the underlying coating. Use shockproof packaging during transportation to prevent damage to the coating due to bumps and impacts.

II. Performance Impact of Extreme Temperature and Humidity

HDPE material exhibits characteristics of "brittleness at low temperatures and softening at high temperatures": When the ambient temperature is below -10℃, the coating's toughness decreases, and cracks easily appear during bending and tension; when the temperature is above 60℃, the coating is prone to softening and deformation, which may reduce its adhesion to the steel strand substrate; long-term exposure to high humidity and strong ultraviolet radiation will also accelerate coating aging and shorten its service life, posing a significant challenge to projects in northern winters, southern summers, and coastal areas.

Solutions:

1. Before low-temperature construction, preheat the steel strands indoors at 5-15℃ for at least 4 hours; when the ambient temperature is below 0℃, use a portable hot air blower to lightly heat the coating surface (temperature not exceeding 30℃) to prevent low-temperature brittleness.

2. During high-temperature seasons, prioritize outdoor operations in the early morning or late evening. Provide sunshades for storing the steel strands and use modified HDPE coating products with added UV inhibitors to improve aging resistance.

3. After construction of underground high-humidity projects, promptly seal the ducts to prevent long-term condensation buildup that accelerates coating aging.

III. Coatings are prone to cracking under long-term high stress

In long-term high stress scenarios such as long-span bridges and heavy-load structures, steel strands are continuously subjected to tensile force. If the adhesion between the HDPE coating and the steel strand substrate is insufficient, or if the coating has poor stress cracking resistance, problems such as coating peeling and surface cracking are likely to occur. This not only affects the anti-corrosion effect, but may also lead to prestress loss and high subsequent reinforcement costs.

Solutions:

1. Prioritize products with an environmental stress cracking resistance rating ≥1000h during procurement, as these products exhibit stronger stability under high stress.

2. In high-load areas such as bridge bearings and expansion joints, additionally wrap the steel strands with elastic buffer materials such as rubber strips to reduce the damage to the coating caused by localized stress concentration.

3. After the project is put into use, conduct visual inspections of the exposed parts of the steel strands and the coating near the anchorages every six months. If any minor cracks are found, seal them promptly with specialized HDPE repair adhesive to prevent further damage.

In summary, the advantages of HDPE-coated prestressed steel strands can be maximized through scientific prevention and control. In actual projects, "selecting the right high-quality products + implementing detailed prevention and control" can avoid more than 90% of quality risks caused by defects. As a source supplier, we not only provide modified HDPE-coated steel strands that are resistant to stress cracking and UV radiation, but also offer customized construction technical guidance for different engineering scenarios, comprehensively reducing engineering risks and helping your project avoid quality risks.

If you encounter specific problems such as coating damage or construction in extreme environments during your project, please feel free to contact us. Our technical team can provide targeted solutions. You can contact us via the phone number and email address on our website, or browse our product page. If needed, we can provide you with a quote. Please feel free to contact us.

How to Select the Appropriate Prestressed Steel Wire for Your Project?

What Are the Advantages of HDPE-coated Prestressed Steel Strand?

Whether you'd like to get more info on what, need help with what you're creating anytime… anywhere.

Yuanxian High-tech Material is a company serving a worldwide customers base providing innovative and reliable product solution that recognizes the value of customer care.

Quick Links

Product Category

Subscribe Newsletter

Welcome to subscribe toour email message!