+86 022 2376 3704

+86 022 2376 3704

Dec. 04, 2025

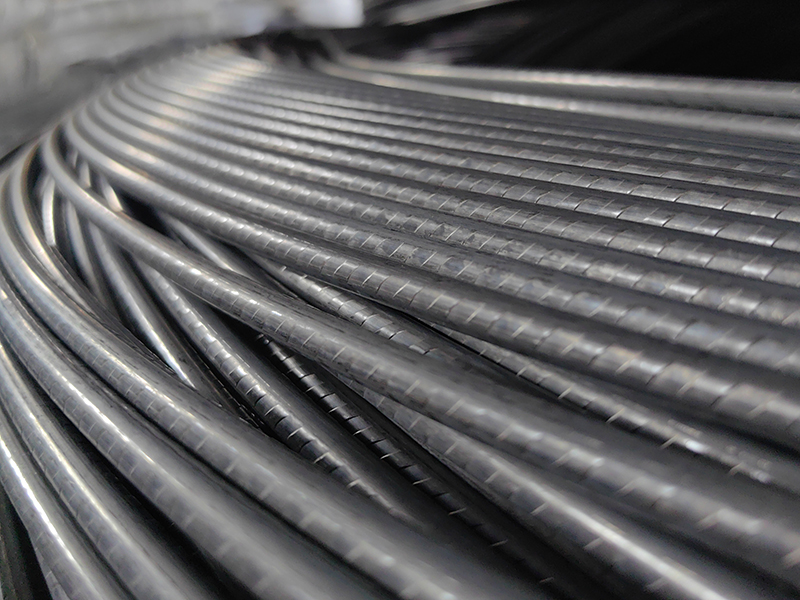

As a professional supplier with many years of experience in the field of prestressed steel wire, we understand that prestressed steel wire is a core load-bearing component of engineering structures. The scientific selection and reliability of its quality directly determine the load-bearing capacity and service life of the project. This article will provide practical advice based on actual project needs, specification compatibility standards, and key points of scientific maintenance, helping you avoid risks and ensure the long-term safety and stability of the project.

I. Actual Project Requirements

1. Clarify Construction and Environmental Conditions:

- Pre-tensioning method: Prioritize steel wires with low relaxation and excellent straightness to effectively reduce tension rebound errors;

- Space-constrained/complex bundle scenarios (such as small components, irregular structures): Prefer 2/3 strand small-diameter steel strands to improve construction flexibility.

- Special environments: In coastal, open-air, and humid environments, galvanized or grease-coated anti-corrosion steel wires should be selected. In cold regions, products with excellent low-temperature toughness should be selected to avoid freeze-thaw damage.

2.Types of Projects Suitable for Different Specifications of Steel Wire:

| Specifications (Diameter/Strength) | Adapted Project Types | Core Advantages |

| 4.0-7.0mm / 1470MPa | Precast floor slabs, pipe piles, and small beams. | It features dense reinforcement, easy construction, moderate cost, and suitability for low-load scenarios. |

| 8.0-10.0mm / 1570MPa | Industrial plants, medium-sized bridges, retaining walls. | It balances strength and toughness, is highly versatile, and is suitable for medium-load requirements. |

| 7.0-9.0mm / 1670MPa | Water conservancy dams and tunnel lining. | Excellent fatigue resistance and impermeability, suitable for engineering projects in harsh environments. |

| 12.7-15.2mm / 1770MPa | Long-span bridges, high-rise buildings, nuclear power plants. | Ultra-high strength, outstanding load-bearing capacity, suitable for high-load, large-span scenarios. |

| 4.0-6.0mm / 1570MPa | Small components, complex fabric structures. | Highly flexible and adaptable to construction scenarios with limited space. |

Note :

- Mainstream specifications cover 4.0-15.2mm. Small diameter (4.0-7.0mm) is suitable for densely reinforced components, while large diameter (12.7-15.2mm) is suitable for high-load structures. Single wire diameter tolerance ≤ ±0.05mm ensures uniform stress distribution.

- Seismic engineering requires high ductility with elongation after fracture ≥ 3.5%. Low-relaxation steel wire must guarantee a relaxation rate ≤ 2.5% after 1000 hours, a yield strength to tensile strength ratio ≤ 0.85 to ensure long-term stability of your project.

II. Strict Control of Steel Wire Standards

1. Product Compliance Requirements

- Domestic Projects: Prioritize products that comply with GB/T 5223 "Steel Wire for Prestressed Concrete" and GB/T 5224 "Steel Strand for Prestressed Concrete" standards.

- International Projects: Accurate matching with corresponding standards such as ASTM (American Standard) and EN (European Standard). The core difference lies in the American standard emphasizes tensile performance indicators, while the European standard emphasizes corrosion resistance and fatigue strength, ensuring the quality meets your project requirements.

2.Precise Matching of Anchors

The pc steel wire must be strictly matched with the anchorage and tensioning equipment (e.g., small-diameter steel wire should be paired with dedicated small anchorages) to avoid prestress transfer failure due to improper matching. As the original supplier, we can provide one-stop matching anchorages and related equipment and support customized models as needed to ensure compatibility throughout the process.

III. Key Maintenance Measures

1. Installation Phase Protection

During the construction, avoid collisions and scratches between the prestressed steel wire and sharp objects. Tension stress must be strictly controlled within 75% of the tensile strength. Anchorages must be securely installed without loosening; gaps must be sealed promptly to prevent stress concentration or rainwater seepage. Attention to detail directly affects structural safety.

2. Targeted Corrosion Prevention

After tensioning, grouting should be performed promptly. The cement grout strength must be ≥40MPa to ensure complete filling of pores. In high-corrosion-risk areas such as coastal areas, an additional anti-corrosion coating is required. Regularly check for anchorage leaks; if any potential problems are found, contact professionals for repair to prevent further corrosion.

3. Routine Daily Maintenance

Establish a regular inspection mechanism with a cycle of 6-12 months, focusing on checking for problems such as steel wire corrosion, loose anchors, and cracks in the grouting layer. If any abnormalities are found, immediately take measures to repair the grout or replace the affected area. Prolonged overloading of the project is strictly prohibited to avoid irreversible structural damage.

4. Special Environmental Adaptation Maintenance

In humid environments, strengthen ventilation and dehumidification to reduce the risk of corrosion; in cold regions, take anti-freezing measures to avoid freeze-thaw cycles damaging the steel wire and surrounding structure, ensuring stability in different environments. If you have any questions regarding prestressed steel wire selection, please contact us; we will provide you with suitable product selection advice.

Summary

Accurate selection and scientific maintenance of prestressed steel wire are the "double guarantee" of project quality. Only by basing our approach on actual project needs, strictly adhering to compliance standards, and implementing full-cycle maintenance measures can we maximize the service life of the project and solidify its structural safety.

As a source supplier with several decades of production experience and service accumulation, we have won the long-term trust of numerous customers thanks to our stable product quality, one-stop supporting services, and comprehensive after-sales support. If you have any questions about prestressed product selection, procurement needs, or customization inquiries, please contact us via our website phone number, email, or directly click onthe customer service chat message. We will provide you with a professional solution to meet your needs!

What Are the Consequences of Substandard Relaxation Rate in Prestressed Steel Wire?

How to Address Common Problems with HDPE Coated Prestressed Steel Strand?

Whether you'd like to get more info on what, need help with what you're creating anytime… anywhere.

Yuanxian High-tech Material is a company serving a worldwide customers base providing innovative and reliable product solution that recognizes the value of customer care.

Quick Links

Product Category

Subscribe Newsletter

Welcome to subscribe toour email message!