EN

Aug. 01, 2025

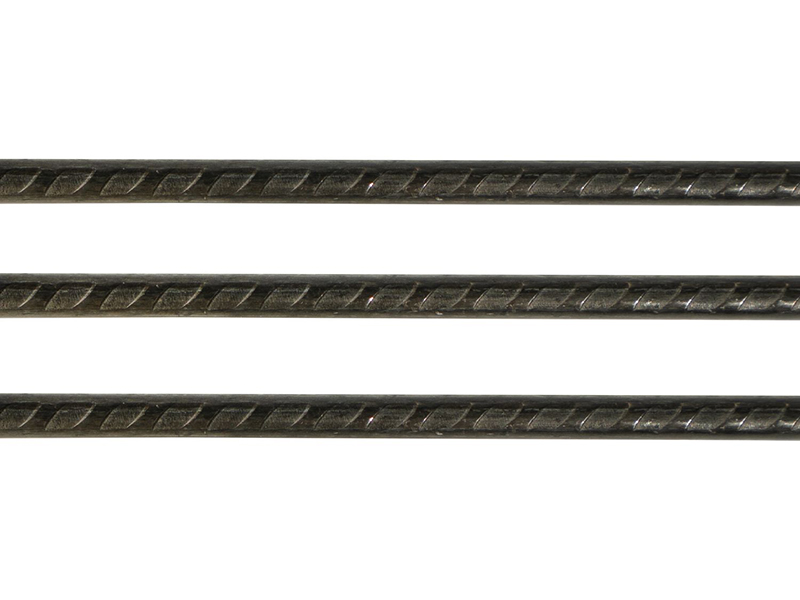

As a supplier focusing on the production of PC indented steel wire, we are well aware of the decisive role of carbon content, a core component parameter, on product performance - it directly affects the mechanical strength, durability and processing adaptability of the steel wire, and is closely related to the long-term stability and safety life of the project. The following is a detailed analysis of the impact of carbon content on the key performance of indented steel wire from a technical perspective to help you accurately select materials according to the engineering scenario. We will also provide you with high-quality products that match your needs based on these characteristics:

1. Changes in strength and hardness

- When the carbon content gradually increases within 0.77%, carbon atoms can significantly improve the strength and hardness of the steel wire by dissolving in ferrite and forming cementite (Fe₃C). For example, a indented steel wire with a carbon content of about 0.80% (such as 82B wire rod, whose carbon content is usually 0.77%-0.85%), has a tensile strength of up to 1860MPa.

- When the carbon content is in the range of 0.6%~0.8%, the steel wire can better balance strength and fatigue resistance, and is suitable for projects such as sleepers and crane cables that need to withstand alternating loads for a long time.

- If the carbon content exceeds 0.90%, the network cementite will split the matrix structure, resulting in a 10%~15% decrease in strength.

2. Changes in plasticity and toughness

- When the carbon content is too low (<0.5%), the steel wire is not strong enough and is prone to plastic deformation under repeated loads, thus shortening its service life.

- Within a certain range (such as 0.5%-0.9%), for every 0.1% increase in carbon content, the elongation after fracture decreases by about 1.5% and the impact toughness decreases by 20%. This is because high carbon makes the crystal structure brittle and easy to break when stressed.

- When the carbon content exceeds 0.80%, the cold brittleness of the steel wire will increase, and the impact energy will be attenuated by more than 40% at -20℃; if it exceeds 0.9%, the brittleness is too large and it is not suitable for dynamic load environments such as bridge vibration.

3. Impact on welding and processing difficulty

- When the carbon content is greater than 0.23%, the heat affected zone of welding is prone to quenching and cracking, and the preheating temperature before welding needs to be increased to above 200°C.

- When the carbon content is greater than 0.85%, not only is it easy to crack during welding due to the carbon element reducing the toughness of the weld, but also surface microcracks will appear during cold drawing due to poor plasticity, resulting in a 25% increase in scrap rate.

4. Impact on stress corrosion and hydrogen embrittlement

- In a chloride ion environment, the stress corrosion cracking rate will increase by 30% for every 0.1% increase in carbon content. Because carbides act as cathodes to accelerate electrochemical reactions.

- The hydrogen diffusion coefficient of high carbon steel wire will decrease by 50%, and the hydrogen solubility will double, causing the hydrogen embrittlement sensitivity to reach its peak.

Summary

In prestressed engineering, the carbon content needs to be reasonably selected according to the application scenario:

- For most projects, prestressed components with a carbon content of 0.6%~0.8% can take into account both high strength and certain toughness, and are widely applicable.

- If the toughness requirements are high (such as lifting rigging), the carbon content can be controlled at 0.5%~0.6% to avoid brittle fracture.

The carbon content of the indented steel wire we produce is designed to comprehensively consider strength, toughness, processability and other requirements, and further optimizes performance matching through heat treatment processes such as lead quenching to ensure that the product can meet the specific requirements of different projects. If you have any related needs, please contact us by phone or email, and we will provide you with suitable products and professional support.

Yuanxian High-tech Material is a company serving a worldwide customers base providing innovative and reliable product solution that recognizes the value of customer care.

+86 180 2006 1362

Haitai Huake Third Road No.1, Huayuan Industrial Zone, Binhai High Tech Zone, Tianjin, china

Quick Links

Product Category

Request a Quote

Welcome to subscribe toour email message!

Send a Message