EN

Aug. 01, 2025

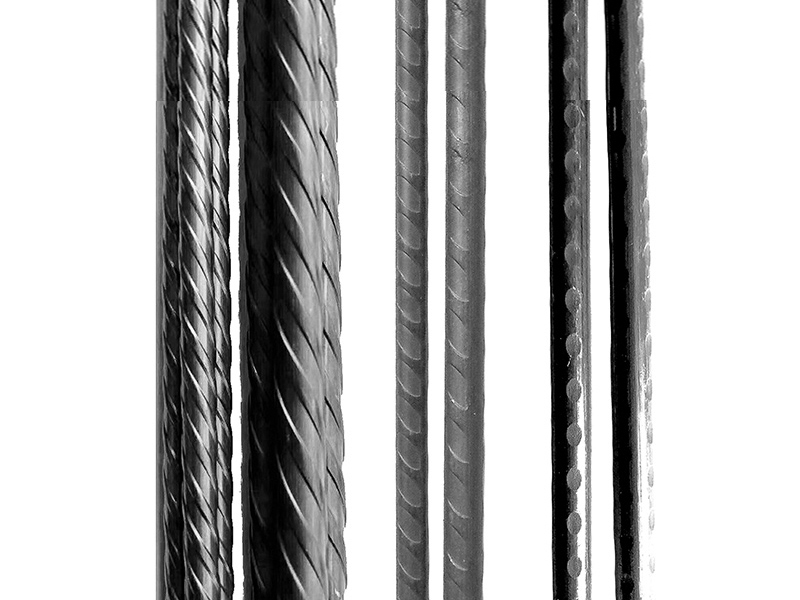

Low relaxation performance is the core ability of PC steel wire to maintain prestress when subjected to long-term stress. It is directly related to the safety and durability of prestressed concrete structures and affects the safety and life of building structures. Relaxation performance is also an important parameter for measuring product quality. When subjected to long-term loads, a low stress relaxation rate can ensure stable prestress and long-term stability of the structure. This performance is mainly affected by the following factors:

1. Influence of Chemical Composition

- Carbon content is the key. When it is within the range of 0.7%-0.9%, it can not only ensure the high strength of the PC steel wire, but also help to improve the low relaxation performance. However, too high a content will increase brittleness, which is not beneficial.

- Alloy elements such as silicon and manganese can improve strength and relaxation resistance through strengthening, but the dosage must be controlled to avoid affecting other properties such as plasticity.

- Impurities such as sulfur and phosphorus will weaken the grain boundaries of the material, reduce purity, and aggravate the relaxation tendency, so their content must be strictly limited.

2.The Role of Internal Structure

- The ideal internal structure of the PC steel wire is a uniform and fine "Sorbite" structure (a microstructure of steel), which can reduce deformation and enhance the ability to resist relaxation.

- The finer the grains and the more uniform the structure, the more conducive to the improvement of low relaxation performance.

- The amount of cold drawing deformation must be reasonable. Moderate deformation can improve strength through work hardening, but excessive deformation will lead to internal stress concentration, increase the risk of relaxation, and affect low relaxation performance.

- The uniformity of the structure is crucial. Inhomogeneity will cause local stress concentration, leading to increased relaxation.

3. The Key Role of Stabilization Treatment Process

- Stabilization treatment (low temperature tempering) is a key process to improve low relaxation performance: the cold-drawn steel wire is heated at 300°C-400°C for a short time under a tension of 30%-50% of the tensile strength to eliminate internal stress and optimize the structure.

- In this process, temperature, time and tension need to be precisely controlled: if the temperature is too low, the stress will not be fully eliminated, and if it is too high, the strength will be reduced; the time needs to match the temperature to ensure the effect while avoiding tissue degradation; if the tension is insufficient, the relaxation effect is poor, and if it is too high, plastic deformation may be caused.

4. Constraints of Use Conditions

- The higher the initial tension stress and the higher the ambient temperature, the more obvious the relaxation of the steel wire, and the more difficult it is to maintain low relaxation performance.

- Relaxation is a cumulative process over time. The relaxation rate is faster in the early stage (such as the first 1000 hours), and then gradually slows down, but it will always increase slowly.

5. Other Related Factors

- If there are scratches, cracks and other defects on the surface of the steel wire, it is easy to become a stress concentration point, induce local deformation, and affect the low relaxation performance.

- During the production process, fluctuations in raw material composition and insufficient control accuracy of process parameters will directly affect the stability and consistency of low relaxation performance.

Summary

To achieve excellent low relaxation performance of PC steel wire, it is necessary to start from chemical composition optimization, microstructure regulation, precise control of stabilization treatment process and other aspects, and ensure its long-term good prestress retention ability through coordinated control of various links. The low relaxation prestressed steel wire produced by our factory (in compliance with ASTM A416, GB/T 5223, EN 10138 and other standards) has been well received by many customers through strict control and optimized design of the above factors. If you also have a purchase plan for PC steel wire, please contact us by phone and email, and we will provide you with customized services.

Yuanxian High-tech Material is a company serving a worldwide customers base providing innovative and reliable product solution that recognizes the value of customer care.

+86 180 2006 1362

Haitai Huake Third Road No.1, Huayuan Industrial Zone, Binhai High Tech Zone, Tianjin, china

Quick Links

Product Category

Request a Quote

Welcome to subscribe toour email message!

Send a Message