EN

Sep. 09, 2025

The core of prestressed steel strand surface treatment is to enhance key properties such as adhesion and corrosion resistance through targeted processes to meet the requirements of different project environments (such as humid and corrosive environments) and construction techniques (pre-tensioning, post-tensioning, etc.). The following are common treatments for the prestressed steel strand we produce, all of which undergo strict process control to meet diverse project requirements:

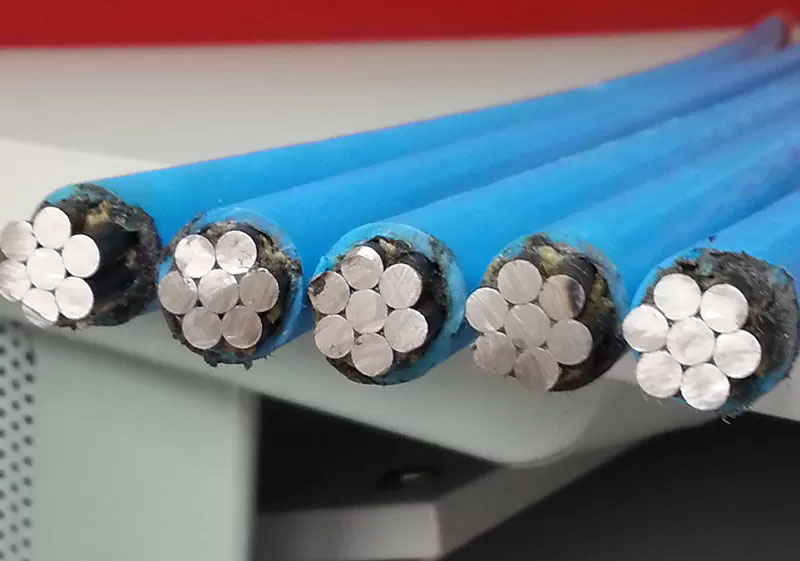

1. Smooth-surfaced Prestressed Steel Strand

The surface is naturally smooth. The raw materials undergo continuous processing during production, including mechanical peeling, pickling, and phosphate coating, to reduce surface contamination and optimize overall quality. This mature process is cost-effective and suitable for over 80% of prestressed structures with standard corrosion protection requirements (such as bridge girders and prefabricated building components). It performs stably in generally dry or slightly humid environments.

2. Indented Prestressed Steel Strand

Circular or spiral indentation, spaced 5-10mm apart, are pressed onto the steel strand surface. This increases the contact area and improves concrete adhesion by 20%-30% compared to plain prestressed strand. This strand is particularly well-suited for prestressing construction, significantly reducing slip during prestress transfer (measured slippage ≤ 1mm), ensuring more accurate and reliable structural stress response. This strand is commonly used in precast beams and slabs.

3. Galvanized Prestressed Steel Strand

Our company utilizes an advanced hot-dip galvanizing process, strictly controlling the zinc coating thickness to 80-120μm. This ensures uniform coverage of the zinc layer across the steel wire surface, protecting the substrate through the sacrificial anode effect and achieving long-lasting corrosion protection. In salt spray testing, the corrosion lifespan is 3-5 times that of ordinary prestressed steel strand, making it particularly suitable for humid environments (such as docks and river bridges) or mildly corrosive environments (such as industrial buildings).

4. Epoxy Resin Prestressed Steel Strand

Our epoxy coating is applied using high-voltage electrostatic spraying, achieving a 0.6-0.8mm thick epoxy coating with an elongation that matches the steel strand (≥3.5%). This coating forms a dense protective film on the surface, completely blocking out corrosive media such as water and oxygen. Our specialized coating equipment and processes ensure coating quality and uniform thickness, ensuring a smooth and successful project. Available options include:

- Single-filament coated type: Each steel wire is individually spray-coated, providing an anti-corrosion lifespan of over 50 years;

- Epoxy-filled type: High-toughness epoxy resin is filled between the steel wires, improving fatigue resistance by 15% and achieving a breaking force retention rate of ≥95%. Suitable for critical projects with extremely high durability requirements, such as nuclear power plants and large-scale water conservancy projects.

5. Unbonded Prestressed Steel Strand

After being coated with a 2-3mm thick, specialized anti-corrosion grease (dropping point ≥ 180°C), the strands are sheathed in a 1.5-2mm high-density polyethylene (HDPE) jacket, achieving complete isolation from the concrete and making them suitable for post-tensioning construction. By eliminating the need for pre-drilled channels and subsequent grouting, construction efficiency is increased by 30% in projects like floor slab and foundation reinforcement, and the jacket offers over 20 years of weather resistance. We utilize high-quality, specialized anti-corrosion grease and HDPE materials and rigorously control our production processes to ensure reliable product quality.

As a professional supplier, we conduct multiple inspections from raw materials to finished product to ensure consistent performance parameters for each treatment. Whether your project is routine or demanding, we can match you with a precise solution and provide the right, high-quality product. Contact us through our official website for a custom quote!

What Are the Criteria for Surface Treatment of Prestressed Steel Strand?

How to Choose the Right Four-Part Anchor Set for Your Project?

Yuanxian High-tech Material is a company serving a worldwide customers base providing innovative and reliable product solution that recognizes the value of customer care.

+86 180 2006 1362

Haitai Huake Third Road No.1, Huayuan Industrial Zone, Binhai High Tech Zone, Tianjin, china

Quick Links

Product Category

Request a Quote

Welcome to subscribe toour email message!

Send a Message