EN

Sep. 09, 2025

In bridge construction, the selection of the four-component anchor set (anchor ring, clip, anchor plate, and spiral rebar) directly impacts the structural safety and lifespan. As a leading manufacturer of anchors, we understand that every parameter and every process plays a crucial role in project success. In bridge construction, the selection of the four-component anchor set (anchor ring, clip, anchor plate, and spiral rebar) must be based on multiple factors, including the bridge structure type, load characteristics, prestressed tendon parameters, and the construction environment. The key consideration is ensuring the safety, adaptability, and durability of the anchoring system. The following are key selection criteria and methods:

1. Matching Specifications to Prestressed Rebar Parameters

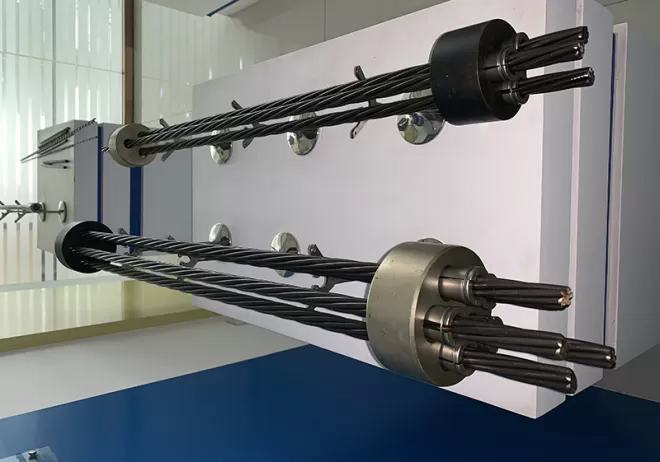

- Diameter and Quantity: The specifications of the anchor ring and clip must strictly match the diameter and number of prestressed tendons (steel strands, wire bundles, etc.). For example, if a single strand is 15.2mm, we need to select anchor rings and clips with corresponding hole diameters. If the strand is composed of multiple strands, our anchor rings must match the number of strands (e.g., 12-hole or 19-hole anchor rings).

- Material Compatibility: When prestressing tendons are made of high-strength steel wire, the clip teeth need to be finer to enhance the grip. For strands, the clips need to conform to the spiral shape to prevent slippage.

2. Select Performance Level Based on Structural Stress Characteristics

- Bearing capacity requirements: The anchorage areas of long-span bridges (such as cable-stayed and suspension bridges) are subject to ultra-high compressive stresses. Therefore, we must use high-strength anchor rings (mostly made of 45-gauge steel or alloy structural steel, with a yield strength ≥830 MPa) and high-hardness clips (Rockwell hardness ≥58) to ensure that pullout resistance meets standards.

- Fatigue performance: Highway bridges must withstand repeated vehicle impacts. Therefore, the four-piece anchor set must pass fatigue testing (e.g., 2 million cycles of loading). In particular, the precision of the clip and anchor ring fit must be ensured to prevent loosening due to repeated stress.

3. Consider the Construction Environment and Durability Requirements

- Corrosive environments: For bridges across rivers and along the coast, anti-corrosion anchors are required. For example, anchor rings with chrome plating (thickness ≥8μm), clips with anti-corrosion coatings, anchor pads made of corrosion-resistant cast iron, and spiral reinforcements with galvanized steel (zinc coating thickness ≥85μm) are required to reduce moisture and salt corrosion.

- Construction space: For narrow areas (such as beam webs), compact anchor pads (80-100mm thick) and short spiral reinforcement (5-6 turns) should be used to avoid conflict with the steel skeleton. For open-air operations, the anchors must be adapted to the operating space of the tensioning equipment.

4. Reference Design Specifications and Project Examples

- Standard Compliance: Our entire anchorage system complies with "Anchors, Clamps, and Connectors for Prestressed Reinforcement" (GB/T 14370). We specifically verify the anchorage's efficiency factor (≥0.95) and ultimate elongation (≥2.0%).

- Case Compatibility: References to proven models from similar bridges (such as continuous beam bridges) can be used. For example, the 15-4 anchorage (four holes, compatible with 15.2mm PC steel strand) is commonly used for 30m precast T-beams. This high-quality anchorage is ideal.

5. The Four-piece Set Must be Fully Compatible

- The hole diameter and angle of the anchor plate must match those of the anchor ring to ensure force transmission is perpendicular to the structural surface.

- The diameter (typically 8-12mm) and number of coils (5-8) of the spiral reinforcement must match the anchor plate dimensions to evenly wrap around stress concentration areas and provide uniform restraint.

In short, the selection of a four-piece anchor system requires careful consideration of multiple factors, including parameter matching, performance compliance, and environmental compatibility. Ultimately, its reliability must be verified through tensioning tests (such as static load anchorage tests) to ensure the long-term safety of the bridge structure.

Please feel free to contact us. We offer the triple guarantee of "factory direct supply, guaranteed quality, and comprehensive after-sales service." We provide a full-cycle service, from parameter customization to on-site technical support, ensuring your bridge anchor system is both compliant and durable. Feel free to contact us for selection advice. Factory direct products offer a more cost-effective solution, ensuring the safety of your project!

Yuanxian High-tech Material is a company serving a worldwide customers base providing innovative and reliable product solution that recognizes the value of customer care.

+86 180 2006 1362

Haitai Huake Third Road No.1, Huayuan Industrial Zone, Binhai High Tech Zone, Tianjin, china

Quick Links

Product Category

Request a Quote

Welcome to subscribe toour email message!

Send a Message