+86 022 2376 3704

+86 022 2376 3704

Dec. 30, 2025

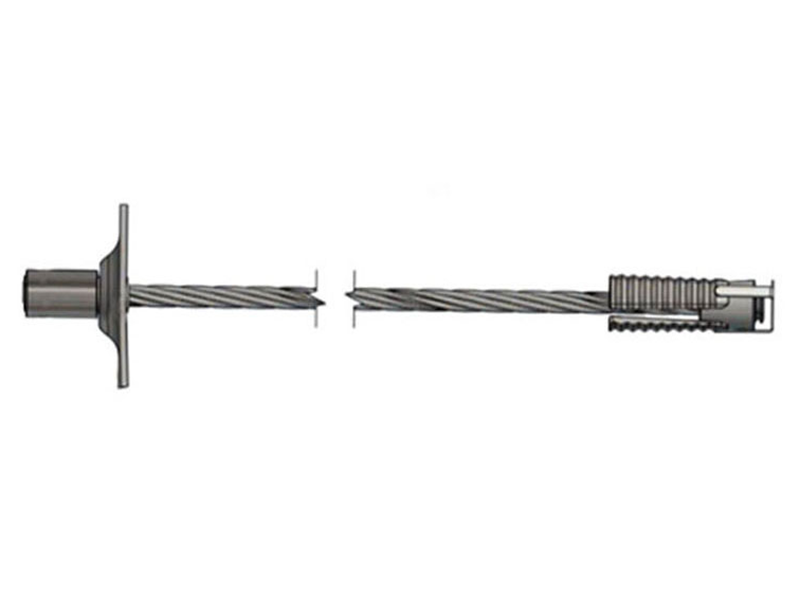

As a prestressed steel strand manufacturer with export qualifications, our products strictly adhere to international standards. Leveraging our end-to-end production line advantages, our prestressed products can precisely meet the requirements of the ISO, ASTM, and EN standards, providing customers with a one-stop solution of "standard compliance + customized production." We have categorized and summarized the specific content of these three standards and the corresponding product requirements to give you a basic understanding of these standards. Below are some differences between the three standards to help you accurately identify the suitable products:

I. Core Standards System

- International Standards (ISO 6934-4/ISO 15630-3): Universal benchmark standards, adaptable to projects in multiple regions, with standardized testing methods. Our factory can mass-produce steel strands of mainstream strength grades such as 1860MPa. From raw material rolling to stress relaxation testing, the entire process conforms to ISO specifications, meeting the general procurement needs of multinational projects.

- US Standard (ASTM A416/A416M uncoated, ASTM A421 galvanized): Graded (e.g., Grade 270 ≈ 1860MPa), low-relaxation models are marked with "L", adapting to North American infrastructure engineering design practices. Our factory maintains a large inventory of US Standard Grade 270 low-relaxation steel strand, supporting rapid production scheduling. Our products are ASTM certified, and no additional compliance testing is required for export to North America.

- European Standard (EN 10138-3): Stringent requirements for relaxation level (Class 1/2/3), coating durability, and fatigue performance, representing a core threshold for EU market access. Our factory has the capacity for mass production of European Standard Class 2 and above steel strand, covering all special processes such as epoxy coating and unbonded construction. Our products come with CE certification and support third-party testing and inspection.

II. Key Technical Differences

1. Strength Grading and Relaxation Performance

ISO uses strength values (e.g., Y1860S7), with a relaxation rate ≤2.5% after 1000 hours; the American standard Grade 270 low relaxation grade has the same limit; the European standard has the finest grading, with Class 1 relaxation rate ≤1.5%, making it the preferred choice for high-end projects.

Our factory can produce fully relaxed grade products on demand, and the measured stress relaxation performance is 5%-10% better than the standard limit, significantly improving the stability of engineering structures.

2. Mechanical and Dimensional Accuracy

ISO/EN gauge length 200mm elongation ≥3.5%; American standard gauge length ≥610mm, elongation ≥3.0%; the European standard has the strictest dimensional tolerance requirements, directly affecting the compatibility of anchorages.

Our factory uses high-precision wire drawing equipment, achieving a dimensional tolerance control accuracy of ±0.03mm, perfectly matching various imported anchorages and avoiding on-site installation compatibility issues.

3. Corrosion Protection and Special Processes

The American standard ASTM A421 specifies a separate galvanizing process; the European standard has more systematic requirements for epoxy coating adhesion and corrosion resistance testing.

Our galvanized steel strand has a zinc coating thickness ≥275g/㎡, and our epoxy-coated steel strand has passed salt spray tests exceeding 1000 hours, meeting the long-term usage requirements of marine engineering and highly corrosive environments.

III. Source Factory Selection

- North American Projects: We prioritize our ASTM A416 Grade 270 low-relaxation steel strand.

We have ample stock, support customization, and offer delivery times 3-5 days faster than the industry average.

- EU Projects: We directly supply EN 10138-3 Class 2 and above products, with CE certification and support for fatigue performance testing, helping clients quickly pass project acceptance.

- Multinational Projects: Based on ISO standards, our factory can provide standard conversion certification reports to ensure that products meet the requirements of projects in multiple regions simultaneously, reducing procurement risks for our clients.

As a source factory, we have ample raw material reserves, supporting bulk customization and centralized procurement, and providing a full-chain service from quotation, production, testing to booking and shipment.

Choosing us not only ensures you receive high-quality products that meet standards, but also provides professional technical selection guidance, making your procurement process worry-free. You can contact us directly through our official website, phone number, and email to obtain the best quote!

How to Choose the Right Strength Grade for Prestressed Steel Strands?

What Are the Corrosion-resistant Coating Options for Prestressed Steel Strands?

Whether you'd like to get more info on what, need help with what you're creating anytime… anywhere.

Yuanxian High-tech Material is a company serving a worldwide customers base providing innovative and reliable product solution that recognizes the value of customer care.

Quick Links

Product Category

Subscribe Newsletter

Welcome to subscribe toour email message!