+86 022 2376 3704

+86 022 2376 3704

Dec. 17, 2025

In the construction of prestressed projects, ensuring the qualification of every construction procedure is the fundamental requirement for guaranteeing project quality, and the quality inspection throughout the entire construction process is even more crucial. Combining our over ten years’ experience in the production of PC steel strands and supporting construction technical services, we have sorted out the some key points for the quality inspection of the tensioning process.

The quality inspection of prestressed steel strand tensioning must throughout three points: before tensioning, during tensioning and after tensioning, with the core of controlling three key indicators: tension force value, elongation value and anchoring effect. The inspection contents are as follows (just for your reference):

1. Inspection Before Tensioning

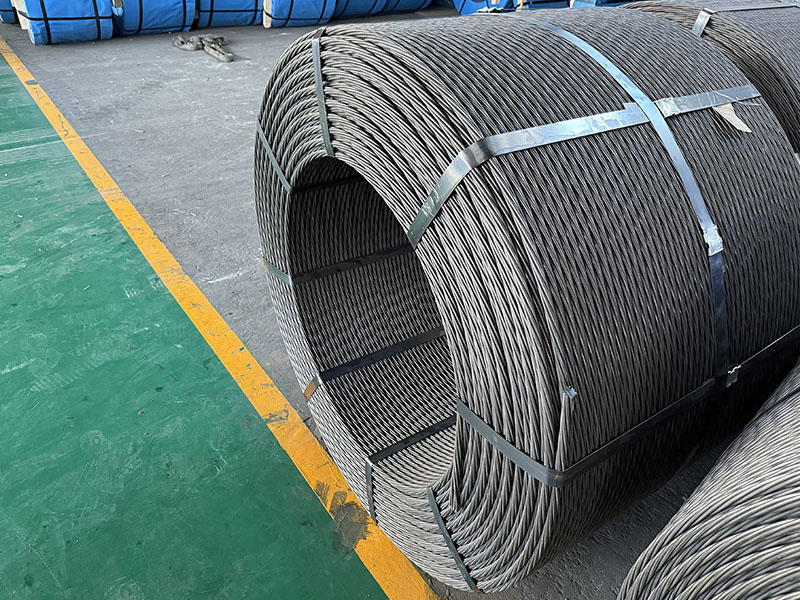

- Verify the specifications, models and mechanical property reports of PC steel strands. All prestressed steel strands produced by our company are accompanied by authoritative inspection reports. Their surfaces are strictly derusted and lubricated, without defects such as rust, oil stains or damage. The anchorages and clips must be accurately matched with the models of PC steel strands. It is recommended to select supporting anchorages homologous to PC steel strands (our company can provide one-stop supply services of PV steel strands + anchorages) to ensure no quality defects such as cracks or deformation.

- Calibrate the certification of tensioning equipment (such as jack and oil pressure gauge) to ensure it is within the validity period and the force value accuracy meets the specification requirements. Check whether the duct is unobstructed and whether the position and angle of the anchor bearing plate are correct to avoid affecting the tensioning effect due to installation deviation.

2. Inspection During Tensioning

- Tension Force Control: Monitor the tension force through the reading of the oil pressure gauge and carry out step-by-step loading (e.g., 0→10% tension control stress→20%→100%). Check the deviation between the oil pressure value and the design value when holding the load at each stage, and the deviation shall be controlled within ±5%. The PC steel strands of our company adopt the high-carbon steel wire rod cold-drawn and twisted process, with stable mechanical properties, which can effectively reduce construction errors caused by tension force fluctuations.

- Elongation Value Verification: Measure the initial length of the PC steel strand under the initial stress (10%~20% tension control stress), record the actual elongation value step by step. The deviation between the actual elongation value and the theoretical elongation value shall be within ±6%. If it exceeds the limit, stop tensioning and investigate the causes.

- Observe in real time whether there is slippage or breakage of the PC steel strand. The number of broken wires shall comply with the specification limits (e.g., no more than 1 broken wire in one bundle of PC steel strands, and no more than 1% of the total number of steel wires per section). At the same time, check whether the components have cracks or abnormal deformation.

3. Inspection After Tensioning

- Check the anchorage retraction within 24 hours after anchoring. The retraction value of the PC steel strand shall be ≤ the limit specified in the specification (usually ≤6mm). Recheck the engagement state of the anchorage clips to ensure there is no loosening or slipping. Our clips supporting anchorages are forged from high-quality alloy steel with precise tooth profile design and strong anchoring force, they can effectively reduce the risk of retraction.

- Fill in the tensioning record and retain data such as tension force value, elongation value and retraction value, they are the core basis for quality acceptance.

The above inspection steps are indispensable in the construction process. They can not only timely identify key problems, but also reduce potential construction hazards, helping your project structure become more stable and have longer service life.

As the source manufacturer of PC steel strands, PC steel wires and supporting anchorages, we can not only provide you with high-quality products complying with multiple standards such as GB and EN, but also rely on our professional technical team to offer you one-stop services from product selection and construction scheme optimization to on-site technical guidance.

If you have relevant needs and technical consulting, please contact us through the official website. Inform us of the specific project parameters and requirements, and we will provide you with accurate quotations and customized solutions timely, we make every effort to solve the problems you encounter in procurement and construction.

What Are the Corrosion-resistant Coating Options for Prestressed Steel Strands?

How Can the Quality of Prestressed Steel Strands be Inspected?

Whether you'd like to get more info on what, need help with what you're creating anytime… anywhere.

Yuanxian High-tech Material is a company serving a worldwide customers base providing innovative and reliable product solution that recognizes the value of customer care.

Quick Links

Product Category

Subscribe Newsletter

Welcome to subscribe toour email message!