+86 022 2376 3704

+86 022 2376 3704

Dec. 17, 2025

As a supplier with many years of experience in prestressed materials and related products, we know that the quality of PC steel strands directly affects the safety and durability of engineering structures. Their qualification must be controlled from core dimensions such as appearance, performance, dimensions, specialized testing, and certificate verification. This article provides the following suggestions for your reference:

I. Visual Inspection

Conduct a comprehensive inspection of each coil to ensure the product's appearance meets the standard requirements:

- The surface should be free of cracks, folds, scars, rust pits, and severe oil stains; no single filament should have localized damage exceeding 10% of its own diameter;

- The nominal diameter deviation should be controlled within ≤±0.4mm, and the circumscribed circle diameter deviation within ≤±0.8mm (compliant with GB/T 5224-2023 requirements);

- The lay length should be evenly distributed with a deviation not exceeding ±5%, and there should be no loosening or broken wires after cutting;

- If it is galvanized or epoxy-coated steel strand, the coating must be intact without peeling, incomplete plating, bulging, or other defects;

- Slight, evenly distributed surface rust and tempering discoloration are permissible and should not affect the product's performance.

II. Performance Testing

Testing must be conducted by a qualified third-party laboratory. Batch sampling must strictly adhere to the sampling rules of GB/T 5224-2023:

- Tensile Test: Specimen length ≥ 600mm. Avoid clamp slippage affecting results. Core tests include tensile strength (general grade ≥ 1860MPa, other strength grades according to corresponding standards), yield strength (≥ 85% of tensile strength), and elongation. All three indicators must meet the standards.

- Relaxation Test: Under a standard environment of 20±2℃, with the initial stress set at 70% of the breaking force, the relaxation rate is measured after 1000 hours and must be ≤ 2.5%.

- Fatigue Test: Only for special engineering requirements. It must meet the requirement of 2 million cycles without fracture.

III. Dimensional Verification

Use precise measuring tools to perform dimensional checks, ensuring deviations meet national standard tolerances:

- Use calipers with a graduation of ≤0.02mm (measured at a distance ≥300mm from the end of the steel strand) to check the nominal diameter and circumscribed circle diameter; use a micrometer to measure the diameter of each filament;

- Measure the lay length at three different locations, take the average value to calculate the deviation, and the deviation should be ≤±5%;

- The outer contour dimensions must strictly conform to the requirements of GB/T 5224-2023 standard.

IV. Specialized Testing

Depending on the specific requirements of the project, the following specialized tests may be conducted:

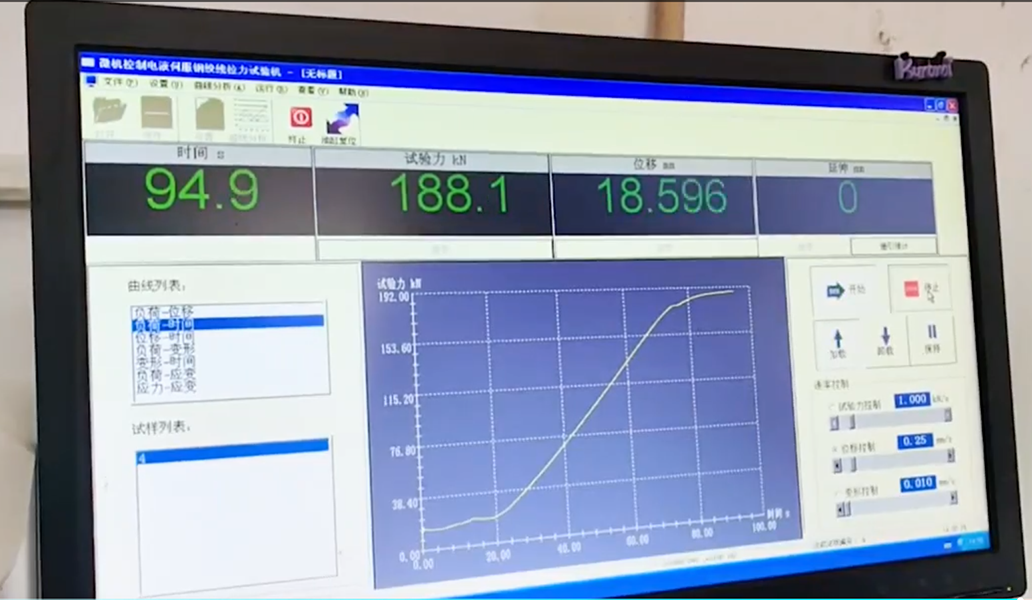

- Skew Tensile Test: Using a 20° skew device, verify the compatibility and collaborative working performance of the steel strand and anchorage;

- Coating Inspection: For galvanized or epoxy-coated steel strands, test the coating thickness and adhesion to ensure that the corrosion resistance meets the standards.

V. Document Verification

- Verify the product certificate of conformity and quality certificate to ensure that the batch number, implementation standard, and test data are completely consistent with the actual product, without any signs of tampering or forgery;

- For imported products, additional verification of customs declaration and commodity inspection report is required to ensure compliant entry;

- In export scenarios, international certification documents such as CE can be provided upon request (if required).

The above are the core points of PC steel strand quality inspection. For customized testing needs, targeted specialized tests can be conducted. All PC steel strands produced by our factory undergo rigorous factory inspection and have a complete quality certification system, supporting re-inspection by third-party testing institutions.

For product certificates of conformity, test reports, and other related documents, or for any technical consultation, please contact us at any time through the official website. We look forward to establishing a long-term and stable cooperative relationship with you.

How to Conduct Quality Inspection During Prestressed Steel Strand Tensioning ?

What Are the Differences Between Ordinary Steel Wire and PC Steel Wire ?

Whether you'd like to get more info on what, need help with what you're creating anytime… anywhere.

Yuanxian High-tech Material is a company serving a worldwide customers base providing innovative and reliable product solution that recognizes the value of customer care.

Quick Links

Product Category

Subscribe Newsletter

Welcome to subscribe toour email message!