EN

May. 29, 2025

Prestressed concrete steel strands are widely used in building systems of various sizes. As the "steel bones" of modern engineering, its quality directly determines the life of the construction project for a hundred years, which has a far-reaching impact.

The quality of the product is a topic that we focus on, but the inspection data in recent years is disappointing: the average unqualified rate of steel strands nationwide is as high as 12.7%, and the rate of mechanical properties not meeting the standards in some areas is as high as 20%. These "inferior" steel strands are pushing countless bridges, buildings, and railways (such as cross-sea bridges, super high-rise buildings, and high-speed rail tracks) to the safety cliff, which is very dangerous.

Therefore, we must refuse to ship inferior products from the source, strictly control the following five core links in production, and truly protect the safety of the project from the source.

1. Reject Inferior Raw Materials

Data from the metallurgical industry show that nearly 30% of manufacturers are still using unrefined steel billets. When inspecting a certain large bridge project, it was found that the tensile strength of the steel strands used in the bridge dropped by 15%. Tracing back to its source, it was found that the manganese content of the wire rods exceeded the standard by 2.3 times; a provincial quality inspection report pointed out that 21% of the samples had scratches exceeding the national standard depth, and 15% had fatal folding defects. These microscopic defects lead to insufficient toughness of the steel, which is very easy to cause stress concentration and fracture under load. Therefore, strictly controlling the quality of raw materials from the source is the first step to reject inferior steel strands.

2. Strictly Control the Processing Technology

The survey shows that the phenomenon of cutting corners in the drawing process is very serious: the temperature of the wire drawing die of a listed company has long exceeded the safety line of 350℃, causing the elongation of steel to plummet by 40%; some companies even reduced the number of drawing passes from 9 to 7, and the cross-sectional shrinkage rate dropped by 28%. There are also precision deviations in the stranding process: when the pitch deviation exceeds 3%, the stress distribution coefficient of the steel strand deteriorates by 1.15 times, and the diameter difference between the center wire and the side wire exceeds the standard by 60%. The loss of control of these processes has seriously affected the various performances of the steel strand. Such steel strands will pose great hidden dangers when used in engineering. Therefore, it is very important to strictly control the various processing technologies of the steel strand in the processing link.

3. Ensure that All Tests Meet the Standards

The chaos in the laboratory is shocking: someone submitted a report saying that 31% of the testing agencies used overdue calipers, with a maximum error of 0.15mm; 45% of the companies arbitrarily shortened the 1000-hour relaxation test to 600 hours, causing the test value to drop by 0.8%. According to a review of a key project accident, the test personnel illegally used a 10x magnifying glass instead of a standard 25x metallographic microscope, resulting in 80% of micro cracks being missed, ignoring product quality, and greatly increasing the accident rate. In order to avoid these painful costs, we must strictly implement meticulous quality inspection details to ensure that all test data of steel strands meet the standards and protect quality.

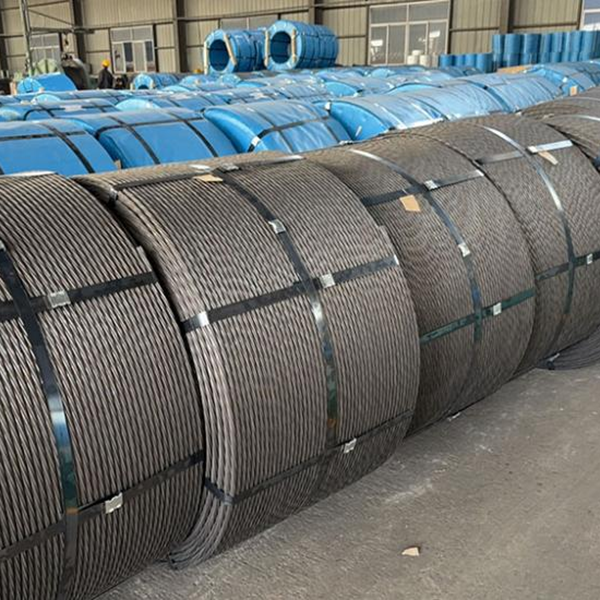

4. Develop Good Storage and Transportation Habits

According to actual measurements at a large port, open-air stacking and unprotected steel strands stored in the ocean atmosphere for 3 months will cause corrosion problems on the surface, resulting in a loss of more than 5% in the cross-section of the steel strands; logistics monitoring records show that the violent loading and unloading of electromagnetic hoists causes the local hardness of the steel strands to increase by HRC5, and the fatigue life is sharply reduced by 40%. In an environment with a humidity of 70%, the annual attenuation of the yield strength of steel strands without anti-rust treatment reaches 3.2%. These careless storage habits will increase the risk of steel strand breakage and cause safety accidents. Therefore, it is imperative to develop reasonable storage and good transportation habits. A good storage environment can extend the service life of steel strands and greatly reduce the probability of risks.

5. Standardize Operations and Avoid Mistakes

Among the incidence rates of various accidents, human operation errors are the most terrible and the most uncontrollable. Serious errors may lead to disasters. For example: an operator mistakenly increased the pulling speed to 15m/min (standard 8m/min), which was 87.5% higher than the standard speed, causing the grain size to deteriorate from level 10 to level 7; an inspector misunderstood the test method, resulting in a misjudgment of the yield strength of 150MPa. What is more serious is that 28% of enterprises have negligence in quality management, and some enterprises have problems with falsifying inspection records, which has led to unimpeded entry of unqualified products into the market, causing the market to flood with inferior products, which not only affects the reputation of the enterprise, but also affects the survival of the enterprise. Therefore, controlling human factors is an indispensable link. Safety is related to you and me. To ensure product quality, we need to start from the details, establish a relevant quality control system, and do a good job of training. Ensuring qualified products is the foundation of the enterprise.

Conclusion

We all know that all quality accidents can be traced back to their source. Therefore, controlling every link in the manufacturing of steel strands is responsible to our customers and ourselves. These safety accidents are also warning us: the quality control of steel strands must build a defense line for the entire industry chain. Every link from the source to the factory is indispensable.

Strictly control the quality of products; establish an industry quality credit evaluation system, and impose corresponding penalties on illegal companies. It is recommended to promote the implementation of intelligent monitoring of the Internet of Things, establish a full-process traceability system, supervise each link, and plug loopholes in each link with a zero-tolerance attitude, so as to truly build a lifeline for project safety. Only in this way can the products produced be high-quality products, which can satisfy customers, and companies with good reputations can also get more cooperation opportunities, thus achieving a win-win situation.

Do you know about bonded and unbonded prestressed steel strands?

Crisis signals of prestressed steel strands --- yellow rust and red rust? (II)

Yuanxian High-tech Material is a company serving a worldwide customers base providing innovative and reliable product solution that recognizes the value of customer care.

+86 180 2006 1362

Haitai Huake Third Road No.1, Huayuan Industrial Zone, Binhai High Tech Zone, Tianjin, china

Quick Links

Product Category

Request a Quote

Welcome to subscribe toour email message!

Send a Message