EN

Sep. 30, 2025

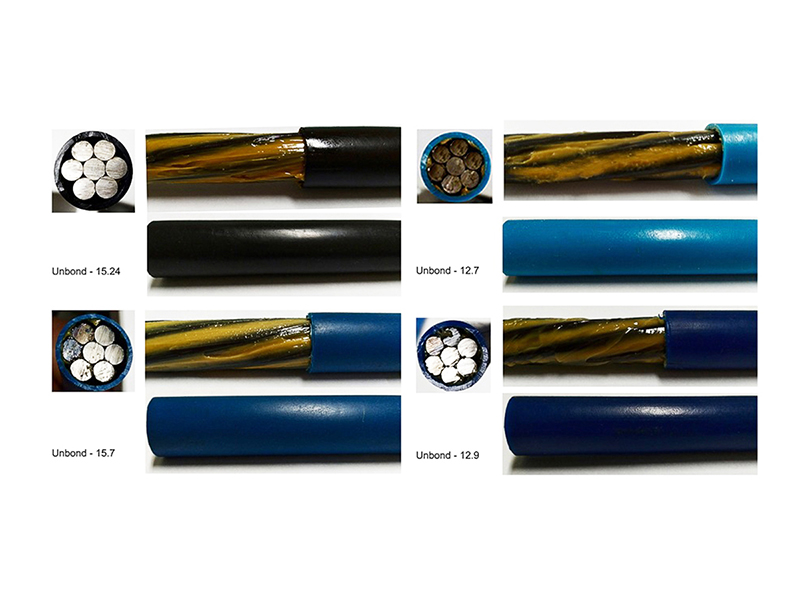

As a leading supplier of unbonded prestressed steel strand, we prioritize long-term corrosion protection and project lifespan. Our unbonded steel strand's corrosion protection system utilizes a multi-layered, coordinated design, providing internal and external protection through "isolation, lubrication, and a physical barrier." Through rigorous selection of high-quality materials and optimized processes, we ensure stable and reliable corrosion protection, fully meeting the 50-100-year design lifespan requirements of construction projects. Its core components are as follows:

1. Inner Layer: Anti-corrosion Base

As the core of the anti-corrosion system, it utilizes high-strength steel strands (tensile strength ≥1720 MPa), primarily 82B/77B high-strength steel in a 1×7 structure. Prior to shipment, it undergoes rigorous surface pickling and phosphating treatments. This not only thoroughly removes scale and oil stains, reducing the risk of initial rust, but also optimizes surface roughness, providing a stronger adhesion base for the middle layer of anti-corrosion grease, ensuring that subsequent protective layers resist detachment.

2. Middle Layer: Chemical Isolation Layer

Apply a 0.5-1.0mm thick layer of specialized anti-corrosion grease evenly to the surface of the steel strands. This grease provides both anti-corrosion and lubrication functions:

- Anti-corrosion: The grease is highly chemically inert, directly isolating corrosive media such as moisture and oxygen from the steel strand surface, forming a primary chemical barrier.

- Lubrication: Allows the steel strands to expand and contract freely within the outer sheath during tensioning and long-term use, preventing friction from damaging the anti-corrosion layer.

- Synergistic Protection: Provides a cushion for the outer HDPE sheath, reducing the risk of damage caused by direct friction between the sheath and the steel strands.

The grease must meet technical requirements for a high dropping point (≥120°C to prevent melting and loss at high temperatures), low volatility, and aging resistance.

3. Outer Layer: Physical Protection

Through an extrusion process, a high-density polyethylene (HDPE) sheath is wrapped around the anti-corrosion grease. The thickness strictly complies with the JT/T 853-2013 standard, maintaining a control range of 1.5 ± 0.5 mm. This sheath serves as the core physical barrier of the anti-corrosion system:

- It protects against mechanical damage during construction, such as collisions and steel bar scratches, preventing exposure of the inner grease layer.

- It blocks the penetration of corrosive media such as moisture and chloride ions, preventing grease loss.

- It forms a "physical + chemical" double barrier with the middle grease layer, preventing failure of any single protective mechanism and ensuring the integrity of the entire anti-corrosion system.

4. Sealing and Protection of the Anchorage Area

The anchorage area is a critical point of stress and corrosion risk for the steel strands, requiring targeted and enhanced protection:

- The anchors should be made of high-quality carbon steel or alloy steel and equipped with sealing devices such as rubber washers to prevent moisture from penetrating through the anchor gaps.

- The anchor pads should be galvanized or epoxy-coated to enhance their corrosion resistance and prevent rust from affecting the overall structural safety.

5. Full-Life Protection

- During the Construction Phase: If minor scratches (≤0.4mm in depth) appear on the sheath, they must be promptly repaired with special tape. If scratches exceed the specified limit, the strands must be partially replaced to prevent the ingress of corrosive media through the damaged area.

- Long-Term Maintenance: Regularly monitor sheath degradation using technologies such as dielectric loss testing and infrared thermal imaging to proactively identify and address potential risks and extend the lifespan of the anti-corrosion system.

Our unbonded steel strand anti-corrosion system utilizes a collaborative design of "base material pretreatment + grease isolation + HDPE sheathing + anchorage sealing," along with comprehensive construction and maintenance measures, to ensure a design lifespan of 50-100 years for unbonded strands in concrete structures. If you have questions about selecting an anti-corrosion system or adapting it for installation, or require customized lengths or corrosion protection levels, please contact us via the phone or email listed on our website. We will provide free technical guidance and provide full assistance.

Yuanxian High-tech Material is a company serving a worldwide customers base providing innovative and reliable product solution that recognizes the value of customer care.

+86 180 2006 1362

Haitai Huake Third Road No.1, Huayuan Industrial Zone, Binhai High Tech Zone, Tianjin, china

Quick Links

Product Category

Request a Quote

Welcome to subscribe toour email message!

Send a Message