EN

Sep. 09, 2025

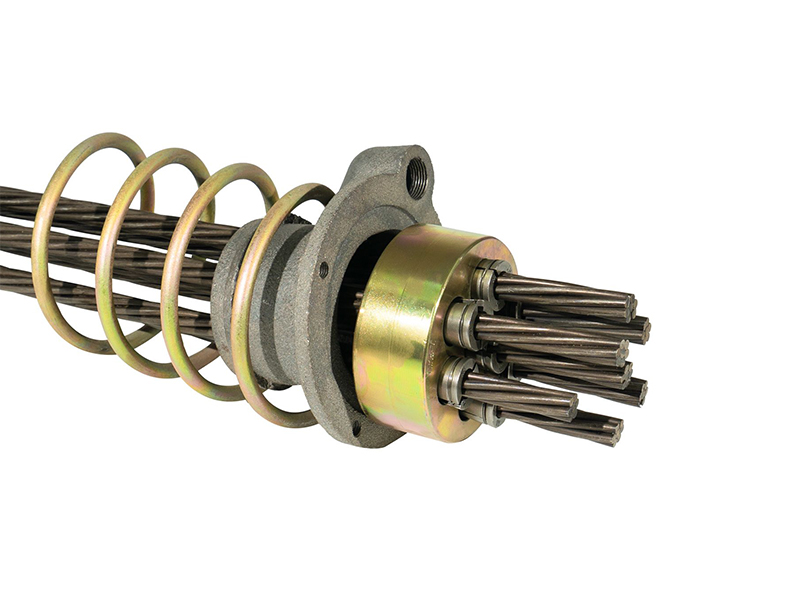

We all know that anchors play a vital role in engineering applications. The appeal and uniqueness of the four-piece prestressed anchor set (anchor plate, clip, anchor pad, and spiral rebar) lies not only in the functional advantages of the individual components but also in the system innovation achieved through their coordinated operation. This is described below:

1. Self-locking Anchor System

- Dynamic engagement of the clip and anchor plate: The clip engages the tapered hole in the anchor plate using a tapered wedging principle. When the jack releases the tension, the strands retract, causing the clip to reverse and lock, creating an irreversible mechanical self-locking structure. This design effectively prevents prestress relaxation and ensures a permanent anchor. Unlike traditional anchors that rely on external fixings, the self-locking structure remains stable even under complex conditions such as vibration and temperature fluctuations. Our clips all incorporate this feature, ensuring a foolproof fastening.

- High-Precision Fit: The alloy steel clips are surface-hardened, ensuring micron-level precision alignment with the tapered holes in the anchor plate. They can withstand steel strand strength exceeding 1860 MPa (equivalent to a tensile force of 186 kg per square millimeter). They maintain a stable engagement even under high-stress conditions, providing a solid foundation for anchoring.

2. Stress Dispersion Mechanism

The four-piece set solves the concrete damage caused by stress concentration in traditional anchors through the synergistic effects of "containment, diffusion, and reinforcement":

- Three-Dimensional Stress Diffusion of the Anchor Pad: A 3-5 cm thick steel or cast iron pad converts concentrated loads on the anchor into surface loads, increasing the contact area by over 40% compared to traditional pads. This evenly distributes the load and effectively prevents concrete collapse.

- Localized reinforcement of spiral reinforcement: Circular spiral reinforcement wrapped around the anchorage creates a three-dimensional restraining force field, significantly enhancing the concrete's crack resistance. Compared to ordinary stirrups, its compressive strength can be increased by over 30%, a significant advantage particularly in heavy-load applications such as bridges and high-rise buildings.

3. Strong Adaptability

- Customizable Form: Anchor plates can be customized to round, flat, or wrap-around (such as the YM15-4) shapes based on actual needs. Round anchor plates are suitable for ample space, such as in bridge beams, while flat anchor plates are more suitable for confined spaces, such as tunnels and subways. Wrap-around anchor plates improve installation efficiency during prefabricated component production and fully meet the steel strand layout requirements of various projects.

- Balanced Lightweight and Durability: The product surface features a silver-gray zinc-nickel alloy anti-corrosion coating, which withstands salt spray tests for over 500 hours without rusting, significantly extending its service life. Precision hole design also reduces weight (e.g., each set weighs only 4 kg), reducing construction and handling while maintaining strength.

4. Improved Construction Efficiency

- Rapid Anchoring: After tensioning is completed, the clips automatically lock, eliminating the need for secondary reinforcement. This reduces the installation time of a single anchor set by 30% compared to traditional methods, significantly improving construction efficiency.

- Strong Fault Tolerance: The spiral reinforcement enhances the toughness of the concrete, ensuring that even minor deviations of ±2mm during anchor installation have no impact on overall performance. This reduces the stringent requirements for construction precision and minimizes the risk of rework.

In summary, the uniqueness of the four-piece prestressed anchor set lies in its innovative system of "mechanical self-locking + coordinated stress distribution + scenario-specific customization," making it an indispensable core component in post-tensioning projects. It not only provides strong guarantees for the safety and durability of projects like bridges, tunnels, and high-rise buildings, but also reduces costs and improves efficiency through efficient construction design.

The anchors produced in our factory undergo rigorous testing. Each set undergoes rigorous testing, including tensioning tests (anchoring efficiency coefficient ≥ 0.95) and fatigue tests (2 million loading cycles without damage), ensuring reliable quality. Welcome to contact us directly by phone or email, we will provide you with professional customized services.

How Do Prestressed Anchors Work?

What Are the Applications of the Four-piece Anchor System in Bridge Construction?

Yuanxian High-tech Material is a company serving a worldwide customers base providing innovative and reliable product solution that recognizes the value of customer care.

+86 180 2006 1362

Haitai Huake Third Road No.1, Huayuan Industrial Zone, Binhai High Tech Zone, Tianjin, china

Quick Links

Product Category

Request a Quote

Welcome to subscribe toour email message!

Send a Message