EN

Sep. 30, 2025

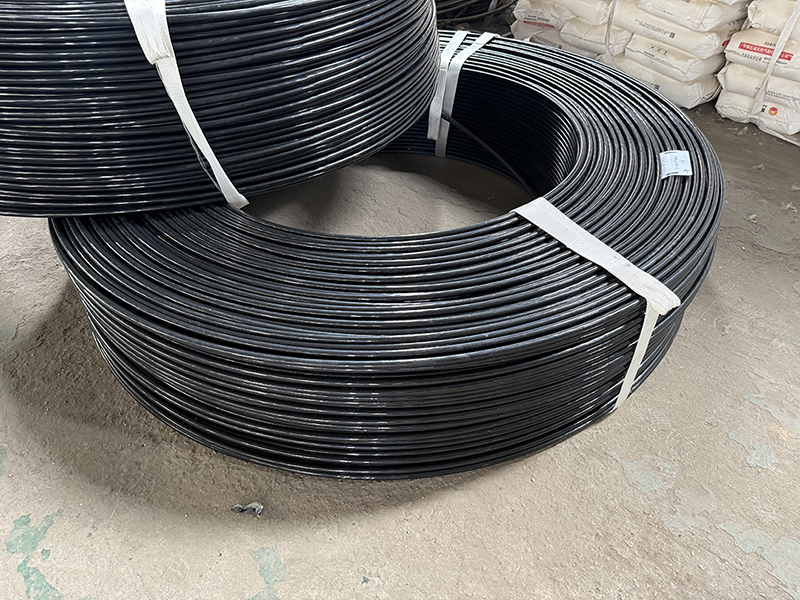

As a core load-bearing component in construction projects, prestressed steel strand's quality directly determines the structural safety and service life. How to accurately avoid procurement and construction risks and minimize financial losses? As a leading supplier of prestressed steel strand with over 10 years of experience, we have combined feedback from thousands of customers and categorized common quality issues with unbonded steel strand into 3 core categories: substandard base material performance, flawed production processes, and ineffective anti-corrosion systems. Their specific manifestations and potential hazards are as follows:

1. Substandard Base Material Performance

The base material is the load-bearing core of the steel strand. Substandard performance can directly lead to insufficient structural bearing capacity, posing a significant safety hazard to the project.

- Substandard Strength: Tensile strength and yield strength do not meet the design levels (for example, the actual measured values for 1860 MPa-grade steel strand are below the standard). This can lead to breakage during tensioning, potentially resulting in construction stoppages and rework, or even collapse of beams, slabs, and other structures. Our factory uses high-quality SWRH82B wire rod that meets the national standard for base material. After production, products are randomly sampled for re-inspection to ensure they meet the strength standards.

- Substandard Elongation: The total elongation at maximum force is less than 3.5% (the national standard requirement for 1860 MPa-grade steel strand). This results in poor toughness and brittle fracture under load, making it unable to buffer stress through deformation, significantly shortening the service life of the structure. Our factory's wire drawing equipment monitors product elongation in real time, ensuring a stable value between 3.8% and 4.2% (higher than the national standard requirement), ensuring the steel strand's toughness meets the project's impact resistance requirements.

- Base material corrosion: Inadequate production protection (e.g., excessive workshop humidity) or lack of moisture-proofing during storage can lead to rust spots and stains on the steel strands. This not only directly weakens the strands' strength (with each 0.1mm increase in rust depth resulting in a 5%-8% decrease in strength), but also penetrates the anti-corrosion grease and damages the HDPE sheath, rendering the entire corrosion protection system ineffective. Our factory utilizes a humidity control system (maintained at 45%-60%) in our workshops and passivates the strands' surfaces. We also equip our storage areas with moisture-proof mats and dehumidifiers, and cover our products with waterproof film. This prevents base material corrosion throughout production and storage.

2. Production Process Defects

Process defects often stem from lax production control. While they may not affect construction in the short term, they can gradually expose problems over the long term, increasing maintenance costs and safety risks.

- Dimensional Deviation: Exceeding tolerances (plus or minus deviations exceeding 0.4mm) in the diameter of steel strands (e.g., the standard 15.2mm specification) or inconsistencies in the length of individual strands (e.g., shorter than the designed length, requiring additional joints) can result in compatibility with standard anchors (e.g., the YM15-7 anchor). Forced installation can easily lead to anchor slippage. Additional joints can increase stress concentration points, creating weak links that could lead to subsequent breakage. Our factory is equipped with precise diameter measuring instruments to monitor the diameter of standard strands, such as 15.2mm strands, ensuring deviations within ±0.2mm. We precisely cut strands to custom lengths with a length tolerance of ≤5mm, ensuring they can be directly installed with anchors.

- Improper tensioning end treatment: Excessive clearance between the anchor and the strand (exceeding 0.2mm), loose connections, or aging or missing rubber seals at the tensioning end allow moisture and dust to penetrate through the end, potentially causing the anchor to rust and seize, and the strand ends to break, affecting tensioning effectiveness and structural prestressing. Our factory uses a custom process for tensioning ends, adjusting the anchor dimensions according to the actual strand diameter to ensure a clearance of ≤0.1mm. The rubber seals are made of age-resistant materials, and the installation integrity is inspected. A matching sealant is also provided to prevent moisture infiltration.

- Rapid sheath aging: Sheaths made from recycled HDPE or low-quality raw materials have poor UV and aging resistance. In outdoor applications, the sheath will crack, become brittle, and fall off within a short period of time (1-2 years), losing its protective effect on the strands within and significantly shortening the strand's service life (normal high-quality sheaths guarantee over 15 years of protection). The sheath raw materials of our factory are made of high-quality materials, and samples are subjected to accelerated aging tests to ensure that the sheath is free of cracks and does not become brittle; the thickness of the finished sheath is controlled at 1.2-1.5mm (higher than the national standard minimum requirement of 1.0mm), which improves the anti-aging and anti-breakage capabilities.

3. Failure of the Anti-Corrosion System

The core advantage of unbonded steel strands focus on their anti-corrosion system. Once this fails, the strands will rapidly corrode, impacting the durability of the project.

- Damaged/Substandard HDPE Sheath: If the sheath thickness is less than 1.0mm (the minimum national standard), the surface is scratched, bulged, or cracked, or bubbles or loose joints are present during production, moisture and chloride ions (such as salt in coastal areas) can penetrate directly into the sheath, accelerating corrosion. In severe cases, strand breakage can occur within 3-5 years. When our factory manufactures the sheath, we add a toughening agent to the inner layer and thicken the outer layer to 1.2-1.5mm to ensure quality. Sheaths must be tested and found to be free of damage before use in construction.

- Poor-quality/Lose Anti-Corrosion Grease: If low-quality grease with a dropping point below 120°C is used, it will melt and leach in the hot summer temperatures. Alternatively, if the grease has poor weather resistance, it will harden in the cold winter and deteriorate in the summer, failing to form a continuous seal. This not only loses its anti-corrosion effect but may also accelerate corrosion of the steel strands. Our factory uses special anti-corrosion grease (dropping point ≥ 150℃) and has passed high-temperature cycle tests to ensure that it will not harden or lose in a year-round environment. During production, we use a high-pressure spraying process to ensure that the grease evenly covers the surface of the steel strand (coating thickness ≥ 1.5mm), forming a complete sealed anti-corrosion layer.

- Poor adhesion between the sheath and the strand: During production, uneven or missing application of anti-corrosion grease, or inconsistent cooling and shrinkage of the HDPE sheath, can create gaps between the sheath and the strand. Moisture and impurities can flow and diffuse within, forming corrosion channels. These problems are difficult to detect, and by the time they are discovered, they often have already caused severe corrosion. Our factory equips the grease application process with a 360° rotating spray head to ensure that no gaps are missed. The sheath is cooled using staged temperature control, gradually cooling to room temperature to avoid uneven shrinkage caused by excessive cooling. Peel tests are performed on sampled finished products to ensure that the sheath-to-strand bond strength is ≥50N/25mm, with no gaps.

These three core quality issues can be proactively avoided through a scientific quality control system. We prioritize "project safety" and "customer value," implementing multi-step quality inspection processes from base material procurement to finished product shipment. We support third-party testing and provide 24/7 access to production and testing data. If you have questions about purchasing, selecting, or adapting your equipment, or have customized requirements (such as special lengths or corrosion resistance levels), we offer free technical guidance and are committed to resolving any issues. Contact us via the phone or email listed on our website, and we'll ensure your project is delivered to the highest quality.

How to Extend the Service Life of Unbonded Steel Strand?

What Are the Quality Inspection Standards for Prestressed Steel Wire?

Yuanxian High-tech Material is a company serving a worldwide customers base providing innovative and reliable product solution that recognizes the value of customer care.

+86 180 2006 1362

Haitai Huake Third Road No.1, Huayuan Industrial Zone, Binhai High Tech Zone, Tianjin, china

Quick Links

Product Category

Request a Quote

Welcome to subscribe toour email message!

Send a Message