EN

Product Tips

Sep. 30, 2025

Advantages of our Titanium Carbide Rods:

Cutting Tools: Titanium rod is used in the manufacture of high-performance cutting tools for machining hard materials. The hardness and wear resistance of TiC make it ideal for drill bits, milling cutters, and other cutting tools.

Wear Parts: Employed in various industrial wear parts that are subjected to high levels of abrasion and wear. Common in industries such as mining, metalworking, and construction.

Cermets: TiC rods can be used as a component in cermet materials, which combine the properties of ceramics and metals. Suitable for applications that require a combination of high hardness and toughness.

Coatings: Used as a precursor for creating wear-resistant coatings on metal surfaces. TiC coatings enhance the durability and lifespan of components exposed to high wear and corrosion.

Abrasives: Utilized in abrasive applications for grinding and polishing hard materials, such as metals and ceramics.

Electrodes: Used in electrical discharge machining (EDM) electrodes due to their conductivity and wear resistance. Suitable for electrical contacts in harsh environments.

Armor and Protective Gear: Employed in the manufacture of lightweight, high-hardness armor for personal and vehicle protection.

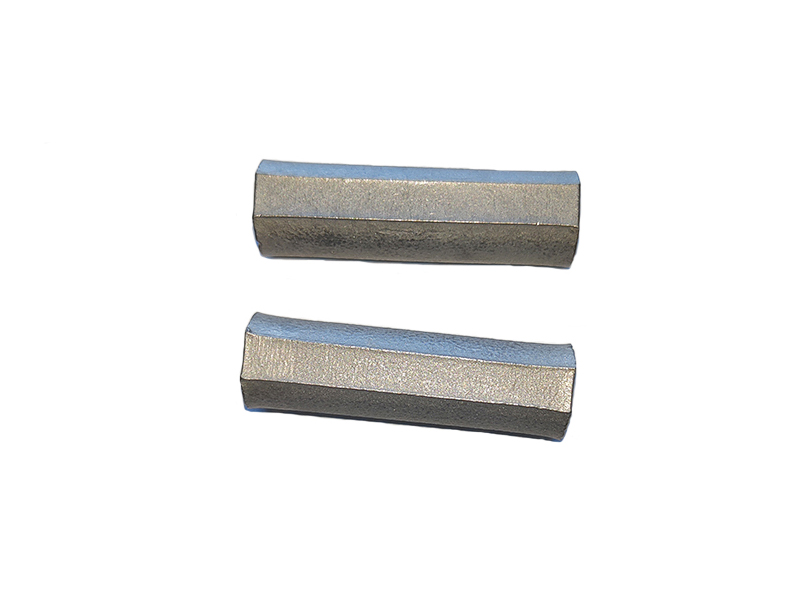

We have grade TM52, GT35 and WSG53 Titanium Carbide Rods available:

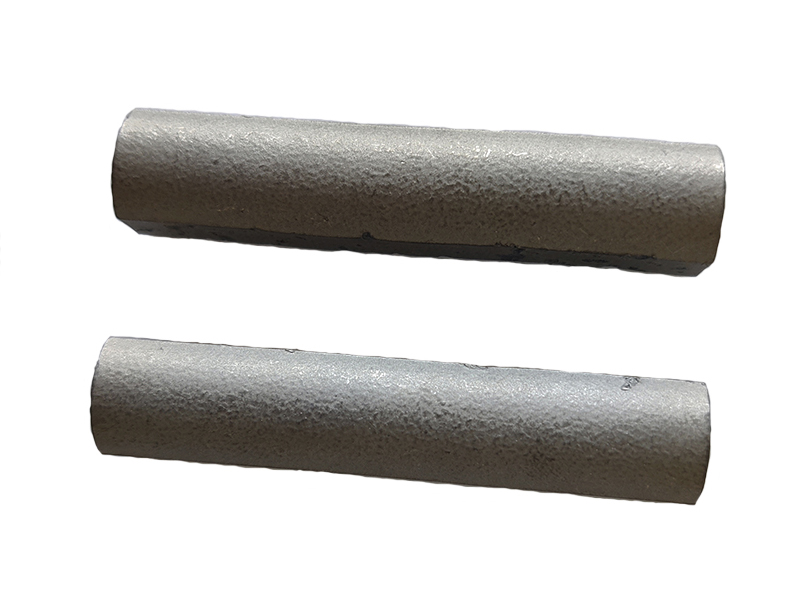

TM52 Titanium Carbide Rod is a composite wear-resistant alloy material with titanium carbide as hard phase and high manganese steel as bonding phase. It has a density of about 6.1g/cm³ and a bending strength of 1400 - 1700MPa. It has work hardening phenomenon and can be cast or arc welded. It is non-magnetic and cannot be machined. It is mainly used for wear-resistant parts of crushing machinery and non-magnetic molds in mining and cement industries.

Application: TM52 Titanium Carbide Rod is used in the wear-resistant parts of crushers, molten high manganese steel is used for casting, and the alloy rods are cast on the working surface of the wear-resistant parts. The two are firmly metallurgically bonded to form composite wear-resistant parts, which can solve the wear problems of high manganese steel and alloy steel wear-resistant parts of various crushers. It is widely used in various impact working conditions such as mining, cement sand making, etc.

Specifications: Common specifications are mainly round rods, including D12×40mm, D12×60mm, D14×50mm, D14×60mm, D14×70mm, D16×50mm, etc., which can also be customized.

| Grade | Binder Phase | Density | Hardness | TRS | Impact Toughness | |

| g/cm3 | Annealing | Hardening | Mpa | J/cm2 | ||

| HRC | HRA | |||||

| Tm52 | Alloy Steel | 6.10-6.30 | Sintered state: HRC≥60 | ≥ 1500 | H2O toughing treatment ≥ 6.0 | |

1. φ12*40

2. φ12*60

3. φ14*50

4. φ14*60(Tic Threaded Rod)

5. φ14*70

6. φ14*80

7. φ14*90

8. φ16*50

9. φ16*60

10. φ16*70

11. φ20*40

12. φ20*60 (Spray-granulated Tic Rod)

13. φ20*80 (Spray-granulated Tic Rod)

GT35 Titanium Carbide is a steel-bonded carbide with CrMo low alloy steel as the matrix (binder phase) and TiC particles as the hard phase (mass fraction 35%, hardness HV3200, second only to diamond). It is characterized by high hardness and high wear resistance, but poor temperature resistance (recommended operating temperature ≤300℃) and corrosion resistance. It is mainly used for cold processing molds, such as cold heading, cold drawing, cold shearing, cold extrusion, cold pressing molds and refractory molds.

Application: Due to its high hardness, high wear resistance and high rigidity, it is suitable for making high-efficiency and long-life tools, dies, gauges, fixtures, jigs and wear-resistant parts. In addition, its good machining performance and heat treatability (performance can be adjusted by quenching and tempering) make it have significant advantages in large molds, complex structure molds, block molds (convenient for replacing damaged modules) and refractory molds.

Product Parameters:

| Grade | Hard Phase | Binder Phase | Density | Hardness | TRS | Impact Toughness | |

| g/cm3 | Annealing | Hardening | Mpa | J/cm2 | |||

| HRC | HRA | ||||||

| Gt35 | TiC | Alloy steel | 6.40-6.60 | ≤48 | ≥86 | ≥1400 | ≥ 3.5 |

1. Carbide Rod: φ13*95mm,

2. Carbide Rod : φ20*90mm.

GT35 Carbide Guide Rollers

| Size | Material | Application |

| Customized Guide rollers’ size varies according to the different wire rods. The main dimensions and structures are: outer diameter and thickness, groove type and bearing hole | Gt35 | Guide Roller (also known as guide wheel) is an indispensable part of wire rod in the rolling process of steel rolling plant. It requires high hardness, good wear resistance (matching the service life with high-quality bearings), good thermal conductivity, and a certain degree of red hardness, especially for high-speed wire rolling (the rolling speed is 80-120m/s). |

1. Carbide Guide Rollers: φ53*φ12*22 (Inner Diameter x Outer Diameter x Height),

2. Carbide Guide Rollers: φ61*φ16*35 (Inner Diameter x Outer Diameter x Height).

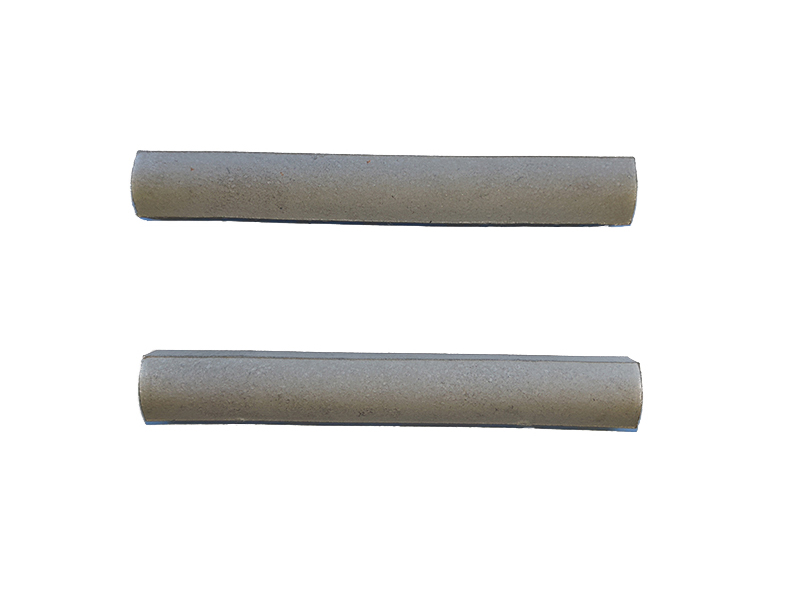

WSG53 Titanium Carbide Rod is a steel-bonded carbide that can solve the wear problem of high manganese steel and alloy steel wear-resistant parts of various crushers. It is widely used in various impact working conditions industries such as mining, cement, sand making, etc.

Product Parameters:

| Grade | Binder Phase | Density | Hardness | Impact Toughness | |

| g/cm3 | Annealing | Hardening | J/cm2 | ||

| HRC | HRA | ||||

| WSG53 | Alloy Steel | 5.9-6.0 | Sintered state: HRC:72.0-75.0 | ≥ 2.5 | |

1. φ12*30 ;

2. φ16*30 .

View our website https://www.yxmaterial.com to find the products you need, request a quote, or contact us for more assistance or additional information.

In addition, we can customize the appearance and size according to the customer's exact requirements. As long as you have your needs, you can choose any specifications and sizes. If you are interested in understanding or inquiring, please feel free to contact us by email or phone!

Yuanxian High-tech Material is a company serving a worldwide customers base providing innovative and reliable product solution that recognizes the value of customer care.

+86 180 2006 1362

Haitai Huake Third Road No.1, Huayuan Industrial Zone, Binhai High Tech Zone, Tianjin, china

Quick Links

Product Category

Request a Quote

Welcome to subscribe toour email message!

Send a Message