EN

Sep. 09, 2025

As a supplier with many years of experience in prestressed steel wire production, we understand the crucial role of material mechanical properties in project safety. The high strength and low relaxation of each steel wire are crucial for ensuring the long-term stability of structures like bridges and high-rise buildings. By rigorously controlling the entire process from raw materials to processing to testing, our prestressed steel wire not only meets the GB/T 5223 standard but is also adaptable to a variety of demanding engineering scenarios. Below are some of our core safeguards:

Ⅰ. Source Control of Raw Material Selection

- High-Purity Wire Rod Selection: We utilize 82B high-carbon steel wire rod that complies with the GB/T 24238 standard. We precisely control the content of key elements—carbon is strictly limited to 0.75%–0.95%, manganese and silicon are added in optimal proportions, and harmful impurities such as sulfur and phosphorus are controlled below 0.035%. This fundamentally prevents impurities that increase steel wire brittleness and strength fluctuations.

- Wire Rod Mechanical Pre-Inspection: Each batch of wire rod is tested for tensile strength, elongation, and other indicators before storage to ensure uniform and stable raw material properties. This prevents subsequent processing steps from being affected by poor wire rod quality and lays a solid foundation for the wire's mechanical properties.

Ⅱ. Scientifically Improving Steel Wire Performance

- Optimizing Deformation Per Pass: Abandoning single, high-deformation drawing, we adopt a multi-pass, step-by-step drawing process, strictly controlling the deformation rate per pass to 5%-15%, ensuring the total deformation precisely matches the target strength grade. This process refines the steel wire's internal grains and increases dislocation density, resulting in a stable tensile strength exceeding 1470 MPa with uniform strength distribution.

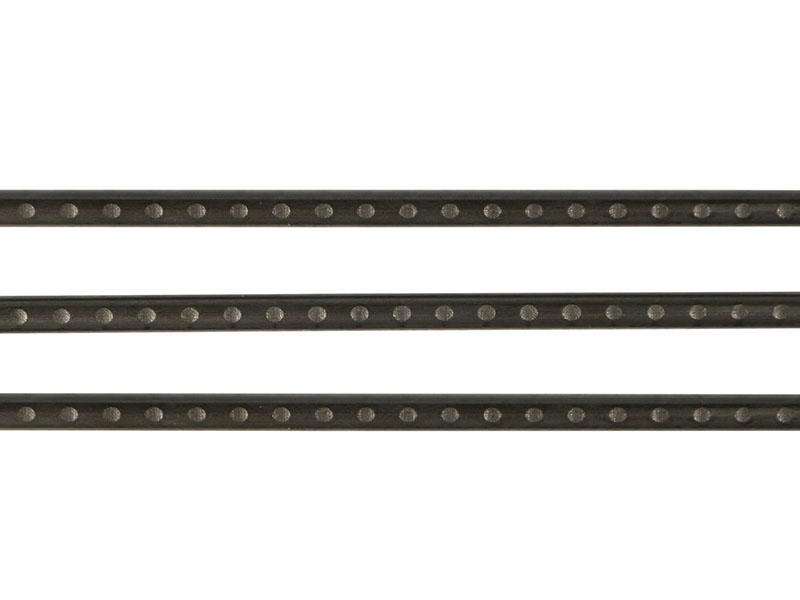

- Stable Drawing Parameters: Maintaining the drawing speed within the optimal range of 5-15 m/s, combined with high-precision carbide dies, prevents localized stress concentrations caused by sudden speed changes or die wear, effectively preventing cracks and surface defects in the wire. Furthermore, we ensure that the wire diameter deviation is within a range of ±0.02-±0.08 mm, minimizing the impact of surface defects on strength.

Ⅲ. Precise Temperature Control Ensures Low Relaxation

- Precise Low-Tempering Parameters: After cold drawing, the steel wire undergoes a stabilization treatment (low-temperature tempering) at 200°C to 350°C. The holding time is flexibly adjusted based on the wire diameter (typically 1 to 3 hours). This process effectively eliminates the internal stresses generated by cold drawing, keeping the wire relaxation rate strictly controlled to ≤2.5% after 1000 hours, meeting low-relaxation steel wire standards.

- High-Precision Temperature Control System: Imported automated temperature control equipment ensures temperature uniformity within the furnace (temperature difference ≤±5°C), preventing local overheating that could lead to strength loss, or insufficient temperature that could lead to incomplete stress elimination, ensuring consistent and standard relaxation performance for each wire.

IV. Full-Process Quality Monitoring

- Online Real-Time Inspection: The production line is equipped with a laser diameter gauge to monitor changes in wire diameter in real time. A high-precision tensile force gauge is used to monitor the pull-out force, ensuring that dimensions and deformation remain within the specified range and preventing fluctuations in parameters from affecting mechanical properties.

- High-Frequency Sampling Inspection: Samples are drawn from each batch of wire to test tensile strength, yield strength, elongation (required to be ≥4%), and other indicators. If any abnormalities are detected, process parameters such as drawing speed and tempering temperature are immediately adjusted to ensure consistent wire performance.

Ⅴ. Multiple Testing Ensures Quality

- Comprehensive Mechanical Properties Testing: Finished products undergo strict testing in accordance with GB/T 5223 standards for tensile strength, total elongation at maximum force, and yield strength to ensure compliance with the specifications of corresponding strength grades, such as 1570 and 1770.

- Simulated Working Condition Relaxation Test: At 20°C ± 2°C, with an initial stress of 70% of the nominal tensile strength, the stress loss of the steel wire is measured over 1000 hours. This ensures that the prestressing can be maintained over a long period of time during actual engineering use, preventing structural safety hazards caused by relaxation.

Summary

From raw material selection to finished product delivery, we coordinate and control five key steps and 16 core processes, ensuring that each prestressed steel wire possesses both high strength to withstand loads and sufficient toughness to prevent brittle fracture, while also meeting the low relaxation requirements for long-term use.

Our products have already served numerous construction projects worldwide. If you require specific strength grades or specifications, we offer customized production, complete with dedicated quality inspection reports, ensuring peace of mind for your project. Please feel free to contact us with any inquiries.

What Are the Advantages of Unbonded Prestressed Steel Strands?

What Are the Criteria for Surface Treatment of Prestressed Steel Strand?

Yuanxian High-tech Material is a company serving a worldwide customers base providing innovative and reliable product solution that recognizes the value of customer care.

+86 180 2006 1362

Haitai Huake Third Road No.1, Huayuan Industrial Zone, Binhai High Tech Zone, Tianjin, china

Quick Links

Product Category

Request a Quote

Welcome to subscribe toour email message!

Send a Message