+86 022 2376 3704

+86 022 2376 3704

Dec. 04, 2025

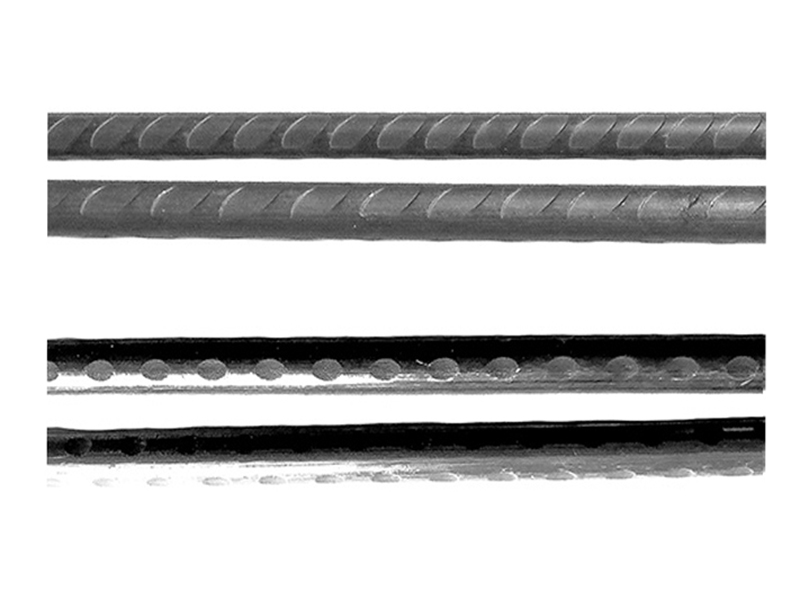

As a seasoned supplier with years of expertise in the prestressed steel industry, we have always adhered to the core principle of "precisely meeting engineering needs and strictly controlling product quality," focusing on the production of indented prestressed steel wires. As a core load-bearing material for prestressed concrete structures, the indentation shape, depth, and spacing of indented prestressed steel wires directly determine the bond anchorage effect, mechanical stability, and application scenario adaptability. Combining our three mainstream products (dot-indented, oval-indented, and diamond-indented prestressed steel wires), this article elaborates on their performance, parameters, advantages, and application scenarios, providing some references for engineering selection and helping you build safer and more efficient high-quality projects.

I. Dot-Indented Prestressed Steel Wires

1. Core Performance

Characterized by uniformly distributed hemispherical or conical indentations on the surface, dot-indented steel wires are a specialized product developed by us for harsh environments, balancing stability and corrosion resistance. Made from high-purity premium wire rods and processed through precision mechanical indentation technology, the product offers a 25%-30% increase in bond strength compared to smooth steel wires with uniform bond force distribution. It causes minimal damage to the wire itself, with a strength retention rate of over 99% and no obvious stress concentration. Its fatigue resistance and corrosion resistance are particularly outstanding, meeting the long-term service requirements in marine environments through salt spray corrosion testing.

2. Indentation Parameters

- Depth: 0.1-0.2mm (shallow indentation design maximizes the retention of the original cross-sectional area and ensures mechanical performance);

- Spacing: 4.5mm-15mm (3-6 times the indentation length, optimized through multiple tests by our company to avoid strength attenuation caused by excessive density).

3. Advantages and Application Scenarios

- Advantages: Adopts a "multi-point anchoring" design; the uniformly distributed hemispherical/conical indentations form decentralized mechanical anchorage with concrete. The absence of continuous grooves avoids stress transmission and reduces the adhesion of corrosive media. Our company additionally provides a surface anti-corrosion coating process to further enhance corrosion resistance.

- Application Scenarios: High-humidity and strong-corrosion environments such as marine engineering and underground utility tunnels, as well as prestressed structures requiring high long-term stability. This product has been successfully applied in numerous coastal bridges and underground comprehensive utility tunnel projects, winning consistent recognition from customers.

II. Oval-Indented Prestressed Steel Wires

1. Core Performance

Oval indentation is the most widely used general-purpose type and our best-selling product with the largest production capacity and customer base. It delivers balanced performance and strong adaptability, with a bond strength over 30% higher than smooth steel wires and a tensile strength of 1470-1860MPa. After low-temperature tempering, its stress relaxation rate is ≤2.5%, fully complying with GB/T 5223-2014 and ISO 6934-2:2024 international standards, and meeting the mechanical requirements of most projects. The rounded, non-angular indentations ensure uniform stress distribution, effectively avoiding local stress concentration.

2. Indentation Parameters

- Depth: 0.02-0.2mm (shallow depth reduces damage to the wire body and ensures product service life);

- Spacing: Standard 5.5±0.5mm (suitable for general components); 8mm-20mm for special steel rods (customizable according to customer needs, balancing grip force and constructability).

3. Advantages and Application Scenarios

- Advantages: It Can be directly embedded in concrete without additional anchorage, adapting to various engineering components and balancing performance and construction efficiency. Our company uses automated production lines to ensure consistent indentation dimensional accuracy, strong bulk supply capacity, and short delivery cycles.

- Application Scenarios: General and large-scale components such as railway sleepers, electric poles, concrete piles, and long-span bridges. This product covers numerous railway, highway, and construction projects nationwide, featuring outstanding cost-effectiveness and serving as the preferred solution for conventional engineering.

III. Diamond-Indented Prestressed Steel Wires

1. Core Performance

Diamond-indented steel wires are customized products launched by us for customers with high bond strength requirements, boasting the most prominent bonding effect among the three types and providing stable anchorage force for structures. Processed with high-precision indentation molds, the product strictly controls indentation depth and edge passivation. Although the diamond shape is prone to stress concentration at the edges, our technological optimization has minimized this impact. It should be noted that this product’s corrosion resistance is weaker than that of dot-indented and oval-indented types, making it more suitable for conventional dry environments.

2. Indentation Parameters

- Depth: 0.03-0.2mm (balances edge anchoring effect and body strength, adjustable on demand);

- Spacing: Standard 5.5±0.5mm; reduced to 3.70-3.90mm for small-diameter wires (dense indentations further enhance bond strength to meet the needs of small-diameter wires).

3. Advantages and Application Scenarios

- Advantages: The angular structure forms strong mechanical interlocking with concrete, preventing slippage under load. It offers controllable costs and adapts to high bond strength requirements in conventional engineering. Our company supports custom indentation parameters based on component size and load requirements to meet personalized project needs.

- Application Scenarios: Conventional building components such as floor reinforcement and concrete piles, as well as rapid construction projects of prefabricated components requiring high bond strength.

IV. Product Selection Recommendations

In summary, selection should be based on three core dimensions: "environment adaptability + performance requirements + component type":

- For corrosive/high-humidity environments: Prioritize our dot-indented prestressed steel wires to ensure long-term structural stability with excellent corrosion resistance;

- For general scenarios: Choose our oval-indented prestressed steel wires as the first option, featuring balanced performance, high cost-effectiveness, and fast delivery to meet most engineering needs;

- For high bond strength requirements: Opt for our diamond-indented prestressed steel wires, whose customized technology fulfills precise load-bearing demands.

As a professional PC Steel Strand supplier, all our indented prestressed steel wires undergo rigorous inspection and testing to ensure compliance with industry standards and customer requirements. If you want to inquire about indented prestressed steel wires, please contact us via the phone number and email on our official website, we can offer product samples and detailed quotations to you at any time. We aim to make your engineering selection more convenient and cooperate with you to create high-quality projects!

Whether you'd like to get more info on what, need help with what you're creating anytime… anywhere.

Yuanxian High-tech Material is a company serving a worldwide customers base providing innovative and reliable product solution that recognizes the value of customer care.

Quick Links

Product Category

Subscribe Newsletter

Welcome to subscribe toour email message!