+86 022 2376 3704

+86 022 2376 3704

Price And Market Trend

Oct. 29, 2025

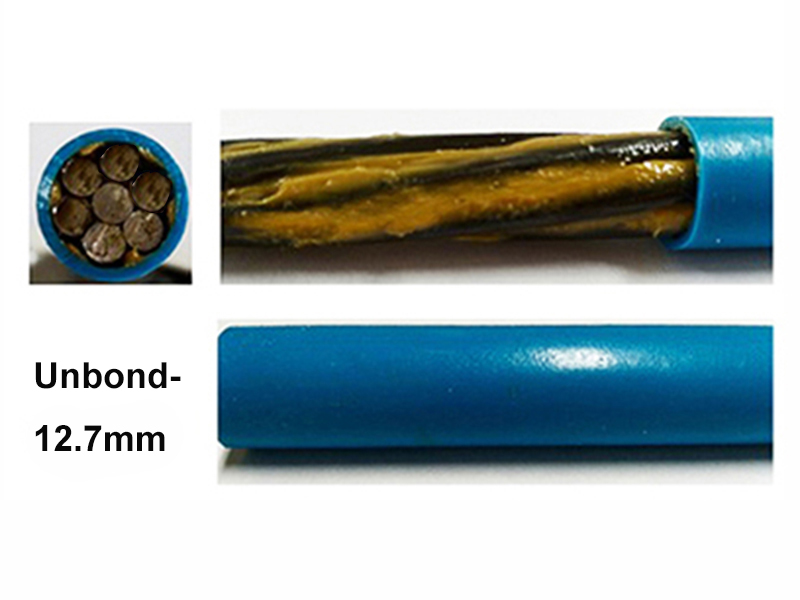

With the deepening of global infrastructure construction and the evolution of engineering technologies, unbonded prestressed steel strand, as a core material for prestressed engineering, is undergoing accelerated upgrades toward high performance, greenness, and intelligence to adapt to increasingly complex engineering scenarios and demanding market demands. Our factory is deeply engaged in the prestressed steel strand industry and has accumulated extensive experience in the research, development, and production of unbonded prestressed steel strand and epoxy-coated steel strand. Our products strictly comply with industry standards such as GB/T 5224. Our reliable quality has made us a core material supplier for numerous key projects. Based on industry developments, the future development trends of unbonded prestressed steel strand can be summarized into the following key directions:

1. Material Performance Upgrade

High strength and low relaxation remain the core research and development priorities, with products with strength grades of 1960 MPa and above becoming the mainstream market development direction. Through technologies such as micro-alloyed wire rod optimization, drawing process improvement and intelligent stabilization treatment, we can solve the industry problem of "high strength and high plasticity", and simultaneously improve the product's fracture toughness, fatigue strength and extreme temperature adaptability, accurately meeting the extreme requirements of material mechanical properties for ultra-long span bridges, deep buried tunnels, super high-rise buildings, etc.

2. Iterative Upgrades in Anti-Corrosion Technology

- Environmentally friendly anti-corrosion lubricants are gradually replacing traditional products, reducing the environmental impact during production and use.

- Double-layer sheathing and improved HDPE (high-density polyethylene) sheathing processes are rapidly gaining popularity. Combined with coating adhesion enhancement technology, these technologies significantly extend product life in harsh environments such as marine salt spray, moist soil, and chemical corrosion, making them ideal for applications such as cross-sea bridges and coastal infrastructure.

3. Production Processes Are Evolving Toward Green and Low-Carbon

Green manufacturing has become an industry consensus. Environmentally friendly processes such as dry sheathing are rapidly replacing traditional grease filling processes, reducing energy consumption and pollutant emissions in the production process. Furthermore, the use of automated production lines (such as intelligent temperature control and stabilization systems and unmanned coating lines) continues to increase, achieving the triple goals of "efficient production, low carbon emissions, and consistent quality," in line with the global trend of green industrial transformation.

4. Efficient Construction Processes

To address construction pain points in specialized engineering scenarios, our technology R&D focuses on breakthroughs in both customized tools and process optimization:

- Developing lightweight tensioning equipment and modular anchoring systems to address operational challenges in tunnel lining and confined space construction.

- Process optimization reduces prestress loss, improves construction accuracy and efficiency, and achieves cost reduction and efficiency improvement, meeting the construction needs of complex projects such as urban renewal and underground utility corridors.

5. Market Size Continues to Expand

Global infrastructure investment (such as urban renewal in China, cross-border railways in Southeast Asia, and energy infrastructure in South America) and the advancement of major projects, coupled with upgrades in traditional sectors and expansion into emerging ones, will continue to unleash market demand. The market of unbonded prestressed steel strand is expected to maintain steady growth in the coming years, with high-end, high-performance products expected to significantly increase their market share, becoming the core driver of industry growth.

6. Applications Expand Across Multiple Industries

Beyond traditional core applications such as bridges, railways, and civil construction, unbonded prestressed steel strand, due to its excellent performance, is poised for breakthroughs in emerging applications such as wind turbine foundation anchoring, underground utility corridors, and nuclear power plant containment. It will become a key material for specialized engineering structures, further unlocking market growth potential.

Overall, the future development of unbonded prestressed steel strand is driven by both technological innovation and market demand: breakthroughs in technical bottlenecks through material, process, and intelligent upgrades, and the continued expansion of its application scenarios and market size alongside global infrastructure upgrades.

Leveraging our accumulated expertise, we offer customized products and services tailored to meet diverse project requirements, including high strength, high corrosion resistance, environmentally friendly and low-carbon solutions, and intelligent monitoring. We also offer free sample delivery and conduct comprehensive quality inspections to ensure our products meet project requirements. We provide cost-effective solutions and help achieve your goals of long life and low maintenance. If you have project material needs, please contact us!

Whether you'd like to get more info on what, need help with what you're creating anytime… anywhere.

Yuanxian High-tech Material is a company serving a worldwide customers base providing innovative and reliable product solution that recognizes the value of customer care.

Quick Links

Product Category

Subscribe Newsletter

Welcome to subscribe toour email message!